Oilseeds Preparation

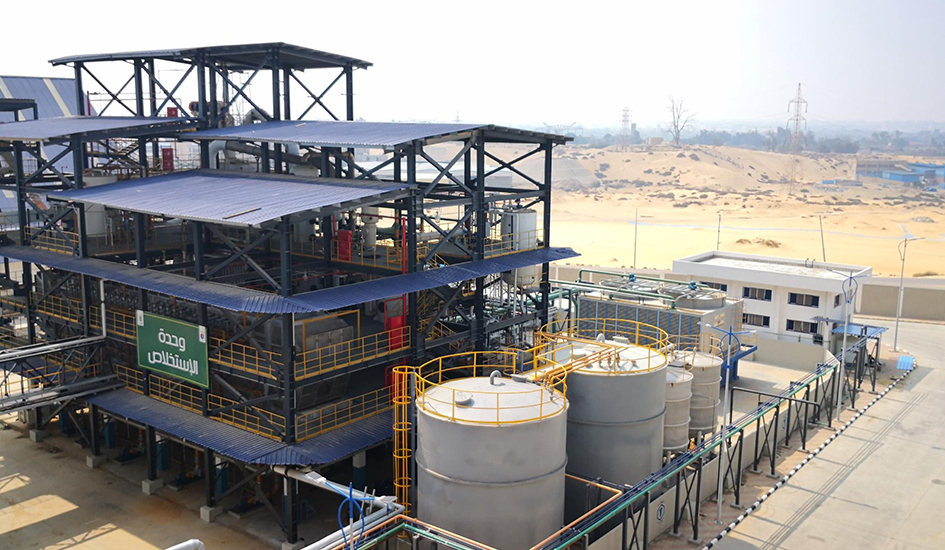

Oilseeds preparation aims to transform oilseeds into high quality flakes, or extruded oilseeds, or pressed cakes desirable for optimal extraction. Myande provides targeted oilseed preparation processes (cleaning, cracking, dehulling, conditioning/cooking, flaking, expanding, crushing, pelletizing, and so on) based on different properties of different oilseeds and clients’ individual requirements.

Myande also provides equipment and technical solutions for meal classification and grinding and adjustment of meal protein content.

Myande oilseeds preparation solutions give full consideration of environmental protection needs, which include dust emission control, heat recovery, minimizing energy consumption, high integration of automation and process, reducing labour intensity, and stable parameters of final products.

We can provide:

- 100-10,000TPD Soybean preparation plant

- 30-2,000TPD Cottonseed preparation plant

- 50-1,000TPD Corn germ preparation plant

- 50-500TPD Flaxseed preparation plant

- 100-5,000TPD Rapeseed/Canola pre-pressing plant

- 100-3,000TPD Palm fruit/Palm kernel pre-pressing

- 50-500TPD Sesame preparation plant

- 100-3,000TPD Sunflower seed preparation plant

- 50-1,000TPD Rice bran preparation plant

- 50-1,000TPD Peanut preparation plant

In addition, we also provide other oilseeds preparation plant, including coconut, linseed, niger seed, shea nut, copra, avocado and etc.

How We Treat Every Seed

01

Reclaiming System

We provide complete storage and reclaim systems with capacity up to 2,000 tons per hour. Depending on the type of silo and the product stored (oilseeds, meal), Myande has developed intelligent customized reclaiming solutions to reduce labor costs and ensure product stability.

Main equipment: Internal Drive Track Reclaimer, External Drive Track Reclaimer, Cantilever Reclaimer

02

Material Handling

Myande can provide complete oilseeds and meal handling solutions with capacity of up to 2,000 tons per hour. Myande conveying equipment adopts wear-resistant material and features long service life, low energy consumption, and reliable operation.

Main equipment: Drag Conveyor, Screw Conveyor, Elevation Drag conveyor

03

Cleaning

The purpose of cleaning is to remove impurities ensuring quality of final products and safety of downstream equipment. We provide you with reliable cleaning solutions depending on the characteristics of oilseeds and impurities content..

Main Equipment: Rotary Magnetic Separator, Plate-type Magnetic Separator, Rotary Screener, Gravity Destoner, Destoner, Sterilizing Cooker

04

Conditioning

Conditioning aims to adjust moisture and temperature of oilseeds, properly prepare oilseeds for pressing and extraction. For oilseeds with good fluidity, such as soybean and rapeseed, we offer Vertical Seed Conditioner. For oilseeds with poor fluidity, we provide Horizontal Rotary Cooker or Vertical cooker.

Main Equipment: Vertical Seed Conditioner

05

Cracking

Oilseeds should be cracked before dehulling or flaking. Myande Oilseed Cracker is designed to crack oilseeds for subsequent processing.

Main Equipment: Loop Chain Conveyor, Oilseed Cracker

06

Hull Separation

Different dehulling processes such as hot dehulling, warm dehulling, cold dehulling are available according to your requirement for the protein content in meal.

Main Equipment: Aspirator

07

Flaking

Myande Oilseed Flaker squeezes prepared and cracked seeds into thin flakes (thickness from 0.3 to 0.35mm, with good toughness and low powder rate) to ensure minimized oil content in meal and solvent consumption.

Main Equipment: Oilseed Flaker

08

Expanding

Oilseeds can be expanded to modify their internal structure, making solvent penetration and extraction easier. Some anti-nutritional factors in oilseeds are inactivated during expansion, enhancing the nutritional value of the meal. Before solvent extraction, the expanded oilseed flakes are dried and cooled.

01

Reclaiming System

We provide complete storage and reclaim systems with capacity up to 2,000 tons per hour. Depending on the type of silo and the product stored (oilseeds, meal), Myande has developed intelligent customized reclaiming solutions to reduce labor costs and ensure product stability.

Main equipment: Internal Drive Track Reclaimer, External Drive Track Reclaimer, Cantilever Reclaimer

02

Material Handling

Myande can provide complete oilseeds and meal handling solutions with capacity of up to 2,000 tons per hour. Myande conveying equipment adopts wear-resistant material and features long service life, low energy consumption, and reliable operation.

Main equipment: Drag Conveyor, Screw Conveyor, Elevation Drag conveyor

03

Cleaning

The purpose of cleaning is to remove impurities ensuring quality of final products and safety of downstream equipment. We provide you with reliable cleaning solutions depending on the characteristics of oilseeds and impurities content. In addition, we provide hull sterilizing process and bring benefits to customers.

Main Equipment: Rotary Magnetic Separator, Plate-type Magnetic Separator, Rotary Screener, Gravity Destoner, Destoner, Sterilizing Cooker.

04

Conditioning

Conditioning aims to adjust moisture and temperature of oilseeds, properly prepare oilseeds for pressing and extraction. For oilseeds with good fluidity, such as soybean and rapeseed, we offer Vertical Seed Conditioner. For oilseeds with poor fluidity, we provide Horizontal Rotary Cooker or Vertical cooker.

Main Equipment: Vertical Seed Conditioner

05

Flaking

Myande Oilseed Flaker squeezes prepared and cracked seeds into thin flakes (thickness from 0.3 to 0.35mm, with good toughness and low powder rate) to ensure minimized oil content in meal and solvent consumption.

Main Equipment: Oilseed Flaker

06

Cooking

The purpose of cooking is to adjust temperature and moisture of oilseeds prior to mechanical pressing so as to maximize oil yield. Two types of cookers are available, namely vertical and horizontal cookers. Vertical cookers feature high steaming intensity and small floor space, while horizontal cookers have high output and low energy consumption.

Main Equipment: Horizontal Rotary Cooker, Vertical Cooker

07

Pressing

We provide both pre-pressing and full pressing solutions according to clients’ requirements for oil yield. Pre-pressed cakes are sent to solvent extraction to improve oil yield, while full pressed cakes can be used as animal feed material to improve economic efficiency.

Main Equipment: Oil Drag Conveyor, Oil Settling Tank

01

Reclaiming System

We provide complete storage and reclaim systems with capacity up to 2,000 tons per hour. Depending on the type of silo and the product stored (oilseeds, meal), Myande has developed intelligent customized reclaiming solutions to reduce labor costs and ensure product stability.

Main equipment: Internal Drive Track Reclaimer, External Drive Track Reclaimer, Cantilever Reclaimer

02

Material Handling

Myande can provide complete oilseeds and meal handling solutions with capacity of up to 2,000 tons per hour. Myande conveying equipment adopts wear-resistant material and features long service life, low energy consumption, and reliable operation.

Main equipment: Drag Conveyor, Screw Conveyor, Elevation Drag conveyor

03

Cleaning

The purpose of cleaning is to remove impurities ensuring quality of final products and safety of downstream equipment. We provide you with reliable cleaning solutions depending on the characteristics of oilseeds and impurities content. In addition, we provide hull sterilizing process and bring benefits to customers.

Main Equipment: Rotary Magnetic Separator, Plate-type Magnetic Separator, Rotary Screener, Gravity Destoner, Destoner, Sterilizing Cooker

04

Cracking

Oilseeds should be cracked before dehulling or flaking. Myande Oilseed Cracker is designed to crack oilseeds for subsequent processing.

Main Equipment: Oilseed Cracker

05

Kernel and Shell Separation

We provide tailored designs of sunflower seed dehulling process are delivered to meet your requirement for protein content in extraction meal. One-stage dehulling and two-stage dehulling are available to suit your specific needs.

Main Equipment: Husk & Kernel Separator, Aspirator

06

Flaking

Myande Oilseed Flaker squeezes prepared and cracked seeds into thin flakes with good toughness and low powder rate to ensure minimized oil content in meal and solvent consumption.

Main Equipment: Oilseed Flaker

07

Cooking

The purpose of cooking is to adjust temperature and moisture of oilseeds prior to mechanical pressing so as to maximize oil yield. Two types of cookers are available, namely vertical and horizontal cookers. Vertical cookers feature high steaming intensity and small floor space, while horizontal cookers have high output and low energy consumption.

Main Equipment: Horizontal Rotary Cooker, Vertical Cooker

08

Pressing

We provide both pre-pressing and full pressing solutions according to clients’ requirements for oil yield. Pre-pressed cakes are sent to solvent extraction to improve oil yield, while full pressed cakes can be used as animal feed material to improve economic efficiency.

Main Equipment: Oil Drag Conveyor, Oil Settling Tank

01

Reclaiming System

We provide complete storage and reclaim systems with capacity up to 2,000 tons per hour. Depending on the type of silo and the product stored (oilseeds, meal), Myande has developed intelligent customized reclaiming solutions to reduce labor costs and ensure product stability.

Main equipment: Internal Drive Track Reclaimer, External Drive Track Reclaimer, Cantilever Reclaimer

02

Material Handling

Myande can provide complete oilseeds and meal handling solutions with capacity of up to 2,000 tons per hour. Myande conveying equipment adopts wear-resistant material and features long service life, low energy consumption, and reliable operation.

Main equipment: Drag Conveyor, Screw Conveyor, Elevation Drag conveyor

03

Cleaning

The purpose of cleaning is to remove impurities ensuring quality of final products and safety of downstream equipment. We provide you with reliable cleaning solutions depending on the characteristics of oilseeds and impurities content. In addition, we provide hull sterilizing process and bring benefits to customers.

Main Equipment: Rotary Magnetic Separator, Plate-type Magnetic Separator, Rotary Screener, Gravity Destoner, Destoner, Sterilizing Cooker

04

Cracking

Oilseeds should be cracked before dehulling or flaking. Myande Oilseed Cracker is designed to crack oilseeds for subsequent processing.

Main Equipment: Oilseed Cracker

05

Kernel and Shell Separation

We provide tailored designs of cotton seed dehulling process to meet your requirement for protein content in extraction meal. The seed kernel is flaked after conditioning, and extrusion or pressing followed by extraction are both available.

Main Equipment: Husk & Kernel Separator, Aspirator

06

Conditioning

Conditioning aims to adjust moisture and temperature of oilseeds, properly prepare oilseeds for pressing and extraction. For oilseeds with good fluidity, such as soybean and rapeseed, we offer Vertical Seed Conditioner. For oilseeds with poor fluidity, we provide Horizontal Rotary Cooker or Vertical cooker.

Main Equipment: Vertical Seed Conditioner

07

Flaking

Myande Oilseed Flaker squeezes prepared and cracked seeds into thin flakes with good toughness and low powder rate to ensure minimized oil content in meal and solvent consumption.

Main Equipment: Oilseed Flaker

08

Cooking

The purpose of cooking is to adjust temperature and moisture of oilseeds prior to mechanical pressing so as to maximize oil yield. Two types of cookers are available, namely vertical and horizontal cookers. Vertical cookers feature high steaming intensity and small floor space, while horizontal cookers have high output and low energy consumption.

Main Equipment: Horizontal Rotary Cooker, Vertical Cooker

09

Expanding

Oilseeds can be expanded to modify their internal structure, making solvent penetration and extraction easier. Some anti-nutritional factors in oilseeds are inactivated during expansion, enhancing the nutritional value of the meal. Before solvent extraction, the expanded oilseed flakes are dried and cooled.

01

Reception

Fresh palm fruit bunches are stacked on a ramp before entering the following sterilizing process.

02

Sterilizing

Fresh palm fruit bunches are firstly sterilized at high temperature through steam until the palm fruit turn soft and suitable for further processes. The sterilization also ensures that the lipase is broken down.

03

Threshing

Cooked fruits are then sent to the mechanical drum type thresher, which effectively separates the fruits from the bunches.

04

Pressing

Palm fruits are firstly mashed and then fed to the double-screw oil press where the crude oil is extracted.

05

Crude Oil Purification

Crude palm oil will go through dilution, settling and screening processes to separate clean oil from sump oil. Clean oil will be sent for refining, while sump oil will go to decanter centrifuge to remove sand and recover partial crude oil.

06

Palm Kernel Separation

Palm nuts are separated from pressed cakes through crushing, air separation, polishing and destoning processes. Then the kernels are separated from the nut shells. Palm kernels can be further processed to extract palm kernel oil, while the shells are sent to the boiler room.

01

Cleaning

The purpose of cleaning is to remove impurities ensuring quality of final products and safety of downstream equipment. We provide you with reliable cleaning solutions depending on the characteristics of oilseeds and impurities content. In addition, we provide hull sterilizing process and bring benefits to customers.

Main Equipment: Rotary Magnetic Separator, Plate-type Magnetic Separator, Rotary Screener, Gravity Destoner, Destoner, Sterilizing Cooker

02

Cracking

Oilseeds should be cracked before dehulling or flaking. Myande Oilseed Cracker is designed to crack oilseeds for subsequent processing.

Main Equipment: Oilseed Cracker

03

Flaking

Myande Oilseed Flaker squeezes prepared and cracked seeds into thin flakes with good toughness and low powder rate to ensure minimized oil content in meal and solvent consumption.

Main Equipment: Oilseed Flaker

04

Cooking

The purpose of cooking is to adjust temperature and moisture of oilseeds prior to mechanical pressing so as to maximize oil yield. Two types of cookers are available, namely vertical and horizontal cookers. Vertical cookers feature high steaming intensity and small floor space, while horizontal cookers have high output and low energy consumption.

Main Equipment: Horizontal Rotary Cooker, Vertical Cooker

05

Pressing

We provide both pre-pressing and full pressing solutions according to clients’ requirements for oil yield. Pre-pressed cakes are sent to solvent extraction to improve oil yield, while full pressed cakes can be used as animal feed material to improve economic efficiency.

Main Equipment: Oil Drag Conveyor, Oil Settling Tank

01

Reclaiming System

We provide complete storage and reclaim systems with capacity up to 2,000 tons per hour. Depending on the type of silo and the product stored (oilseeds, meal), Myande has developed intelligent customized reclaiming solutions to reduce labor costs and ensure product stability.

Main equipment: Internal Drive Track Reclaimer, External Drive Track Reclaimer, Cantilever Reclaimer

02

Material Handling

Myande can provide complete oilseeds and meal handling solutions with capacity of up to 2,000 tons per hour. Myande conveying equipment adopts wear-resistant material and features long service life, low energy consumption, and reliable operation.

Main equipment: Drag Conveyor, Screw Conveyor, Elevation Drag conveyor

03

Cleaning

The purpose of cleaning is to remove impurities ensuring quality of final products and safety of downstream equipment. We provide you with reliable cleaning solutions depending on the characteristics of oilseeds and impurities content. In addition, we provide hull sterilizing process and bring benefits to customers.

Main Equipment: Rotary Magnetic Separator, Plate-type Magnetic Separator, Rotary Screener, Gravity Destoner, Destoner, Sterilizing Cooker

04

Conditioning

Conditioning aims to adjust moisture and temperature of oilseeds, properly prepare oilseeds for pressing and extraction. For oilseeds with good fluidity, such as soybean and rapeseed, we offer Vertical Seed Conditioner. For oilseeds with poor fluidity, we provide Horizontal Rotary Cooker or Vertical cooker.

Main Equipment: Vertical Seed Conditioner

05

Expanding

Oilseeds can be expanded to modify their internal structure, making solvent penetration and extraction easier. Some anti-nutritional factors in oilseeds are inactivated during expansion, enhancing the nutritional value of the meal. Before solvent extraction, the expanded oilseed flakes are dried and cooled.

01

Reclaiming System

We provide complete storage and reclaim systems with capacity up to 2,000 tons per hour. Depending on the type of silo and the product stored (oilseeds, meal), Myande has developed intelligent customized reclaiming solutions to reduce labor costs and ensure product stability.

Main equipment: Internal Drive Track Reclaimer, External Drive Track Reclaimer, Cantilever Reclaimer

02

Material Handling

Myande can provide complete oilseeds and meal handling solutions with capacity of up to 2,000 tons per hour. Myande conveying equipment adopts wear-resistant material and features long service life, low energy consumption, and reliable operation.

Main equipment: Drag Conveyor, Screw Conveyor, Elevation Drag conveyor

03

Cleaning

The purpose of cleaning is to remove impurities ensuring quality of final products and safety of downstream equipment. We provide you with reliable cleaning solutions depending on the characteristics of oilseeds and impurities content. In addition, we provide hull sterilizing process and bring benefits to customers.

Main Equipment: Rotary Magnetic Separator, Plate-type Magnetic Separator, Rotary Screener, Gravity Destoner, Destoner, Sterilizing Cooker

04

Cracking

Oilseeds should be cracked before dehulling or flaking. Myande Oilseed Cracker is designed to crack oilseeds for subsequent processing.

Main Equipment: Oilseed Cracker

05

Cooking

The purpose of cooking is to adjust temperature and moisture of oilseeds prior to mechanical pressing so as to maximize oil yield. Two types of cookers are available, namely vertical and horizontal cookers. Vertical cookers feature high steaming intensity and small floor space, while horizontal cookers have high output and low energy consumption.

Main Equipment: Horizontal Rotary Cooker, Vertical Cooker

06

Flaking

Myande Oilseed Flaker squeezes prepared and cracked seeds into thin flakes with good toughness and low powder rate to ensure minimized oil content in meal and solvent consumption.

Main Equipment: Oilseed Flaker

07

Pressing

We provide both pre-pressing and full pressing solutions according to clients’ requirements for oil yield. Pre-pressed cakes are sent to solvent extraction to improve oil yield, while full pressed cakes can be used as animal feed material to improve economic efficiency.

Main Equipment: Oil Drag Conveyor, Oil Settling Tank

01

Reclaiming System

We provide complete storage and reclaim systems with capacity up to 2,000 tons per hour. Depending on the type of silo and the product stored (oilseeds, meal), Myande has developed intelligent customized reclaiming solutions to reduce labor costs and ensure product stability.

Main equipment: Internal Drive Track Reclaimer, External Drive Track Reclaimer, Cantilever Reclaimer

02

Material Handling

Myande can provide complete oilseeds and meal handling solutions with capacity of up to 2,000 tons per hour. Myande conveying equipment adopts wear-resistant material and features long service life, low energy consumption, and reliable operation.

Main equipment: Drag Conveyor, Screw Conveyor, Elevation Drag conveyor

03

Cleaning

The purpose of cleaning is to remove impurities ensuring quality of final products and safety of downstream equipment. We provide you with reliable cleaning solutions depending on the characteristics of oilseeds and impurities content. In addition, we provide hull sterilizing process and bring benefits to customers.

Main Equipment: Rotary Magnetic Separator, Plate-type Magnetic Separator, Rotary Screener, Gravity Destoner, Destoner, Sterilizing Cooker

04

Cracking

Oilseeds should be cracked before dehulling or flaking. Myande Oilseed Cracker is designed to crack oilseeds for subsequent processing.

Main Equipment: Oilseed Cracker

05

Flaking

Myande Oilseed Flaker squeezes prepared and cracked seeds into thin flakes with good toughness and low powder rate to ensure minimized oil content in meal and solvent consumption.

Main Equipment: Oilseed Flaker

06

Cooking

The purpose of cooking is to adjust temperature and moisture of oilseeds prior to mechanical pressing so as to maximize oil yield. Two types of cookers are available, namely vertical and horizontal cookers. Vertical cookers feature high steaming intensity and small floor space, while horizontal cookers have high output and low energy consumption.

Main Equipment: Horizontal Rotary Cooker, Vertical Cooker

07

Pressing

We provide both pre-pressing and full pressing solutions according to clients’ requirements for oil yield. Pre-pressed cakes are sent to solvent extraction to improve oil yield, while full pressed cakes can be used as animal feed material to improve economic efficiency.

Main Equipment: Oil Drag Conveyor, Oil Settling Tank

01

Reclaiming System

We provide complete storage and reclaim systems with capacity up to 2,000 tons per hour. Depending on the type of silo and the product stored (oilseeds, meal), Myande has developed intelligent customized reclaiming solutions to reduce labor costs and ensure product stability.

Main equipment: Internal Drive Track Reclaimer, External Drive Track Reclaimer, Cantilever Reclaimer

02

Material Handling

Myande can provide complete oilseeds and meal handling solutions with capacity of up to 2,000 tons per hour. Myande conveying equipment adopts wear-resistant material and features long service life, low energy consumption, and reliable operation.

Main equipment: Drag Conveyor, Screw Conveyor, Elevation Drag conveyor

03

Cleaning

The purpose of cleaning is to remove impurities ensuring quality of final products and safety of downstream equipment. We provide you with reliable cleaning solutions depending on the characteristics of oilseeds and impurities content. In addition, we provide hull sterilizing process and bring benefits to customers.

Main Equipment: Rotary Magnetic Separator, Plate-type Magnetic Separator, Rotary Screener, Gravity Destoner, Destoner, Sterilizing Cooker

04

Conditioning

Conditioning aims to adjust moisture and temperature of oilseeds, properly prepare oilseeds for pressing and extraction. For oilseeds with good fluidity, such as soybean and rapeseed, we offer Vertical Seed Conditioner. For oilseeds with poor fluidity, we provide Horizontal Rotary Cooker or Vertical cooker.

Main Equipment: Vertical Seed Conditioner

05

Flaking

Myande Oilseed Flaker squeezes prepared and cracked seeds into thin flakes with good toughness and low powder rate to ensure minimized oil content in meal and solvent consumption.

Main Equipment: Oilseed Flaker

06

Cooking

The purpose of cooking is to adjust temperature and moisture of oilseeds prior to mechanical pressing so as to maximize oil yield. Two types of cookers are available, namely vertical and horizontal cookers. Vertical cookers feature high steaming intensity and small floor space, while horizontal cookers have high output and low energy consumption.

Main Equipment: Horizontal Rotary Cooker, Vertical Cooker

07

Pressing

We provide both pre-pressing and full pressing solutions according to clients’ requirements for oil yield. Pre-pressed cakes are sent to solvent extraction to improve oil yield, while full pressed cakes can be used as animal feed material to improve economic efficiency.

Main Equipment: Oil Drag Conveyor, Oil Settling Tank

01

Cleaning

The purpose of cleaning is to remove impurities ensuring quality of final products and safety of downstream equipment. We provide you with reliable cleaning solutions depending on the characteristics of oilseeds and impurities content. In addition, we provide hull sterilizing process and bring benefits to customers.

Main Equipment: Rotary Magnetic Separator, Plate-type Magnetic Separator, Rotary Screener, Gravity Destoner, Destoner, Sterilizing Cooker

02

Cooking

Sesame seeds are processed in specially designed sesame cooker that features precise control of temperature. Depending on the client's site conditions, the cooker's heat source can be varied (coal-fired, natural gas, biomass energy, etc.). Other features of Myande sesame seed cooker include high output capacity and low energy consumption.

03

Pressing

We provide both pre-pressing and full pressing solutions according to clients’ requirements for oil yield. Pre-pressed cakes are sent to solvent extraction to improve oil yield, while full–pressed cakes can be used as animal feed material to improve economic efficiency.

They trust and choose Myande

More than 1,000 complete plants have been supplied under Myande’s name in around 80 countries since 2003.

Behind every successful project is a great team. Our team is comprised of skilled individuals that share one common goal – Help our clients succeed.

What can we do for you?

We focus on supplying one-stop engineering service covering general layout plan, process design, R&D, equipment manufacturing, automatic control system, data integration, installation, supervision, commissioning, training and etc.

Our custom solutions come from a deep understanding of your needs, and we have the capability to complete each project from the design of the initial concept to manufacturing, installation, commissioning and delivery.

Solution Tailored to Your Needs

General Layout Plan

With a land prepared, the next thing you should consider is planning the general layout, which is a crucial foundation of a sustainable and cost-effective manufacturing.

Turn to us for help and we will present you the design for your plant by considering water, steam, electricity supply and etc.

Process Design

Combining our engineering expertise, industry know-how and practical skills with your knowledge, we provide the optimized and customized process design for your plant.

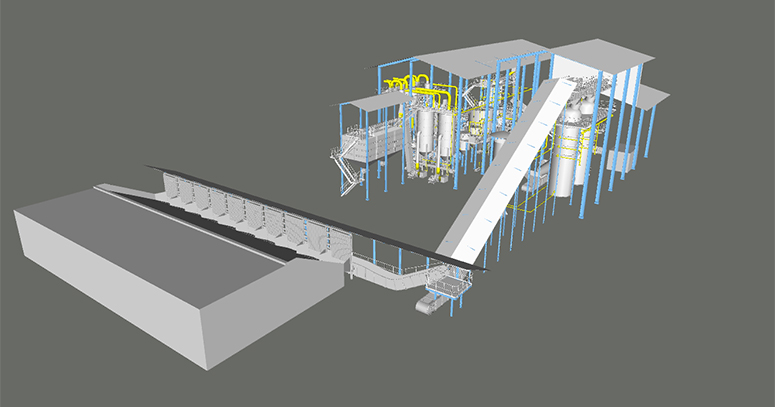

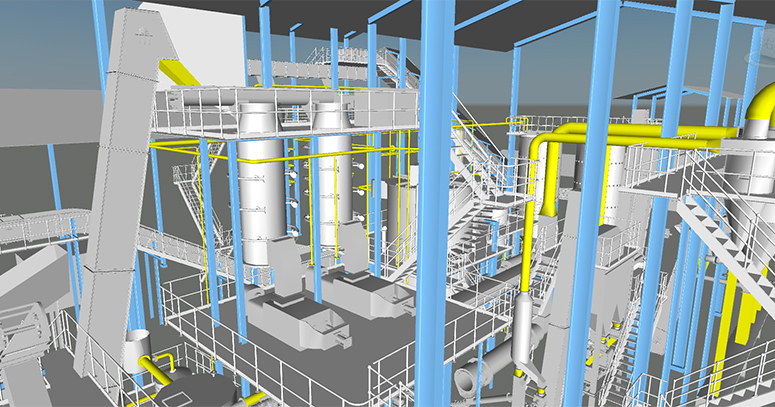

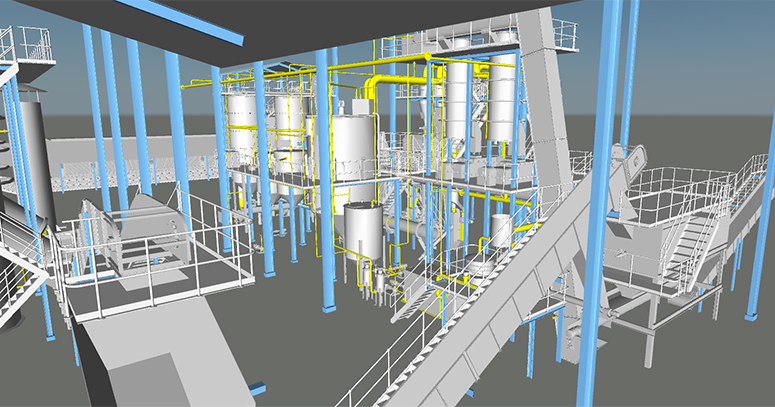

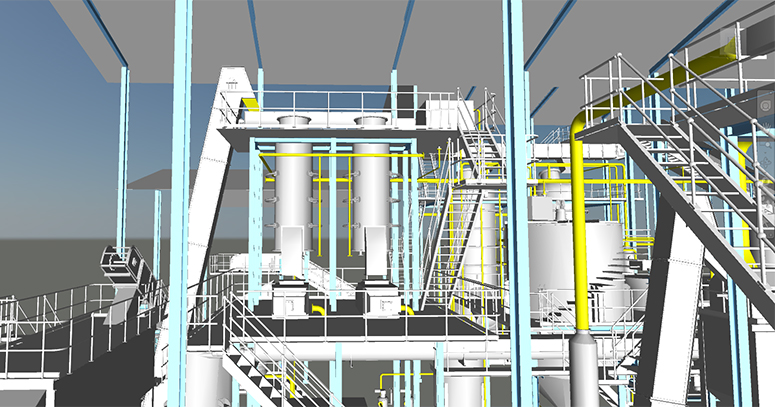

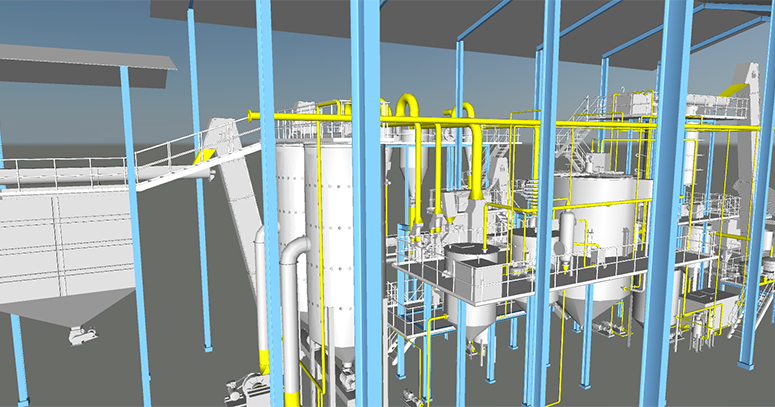

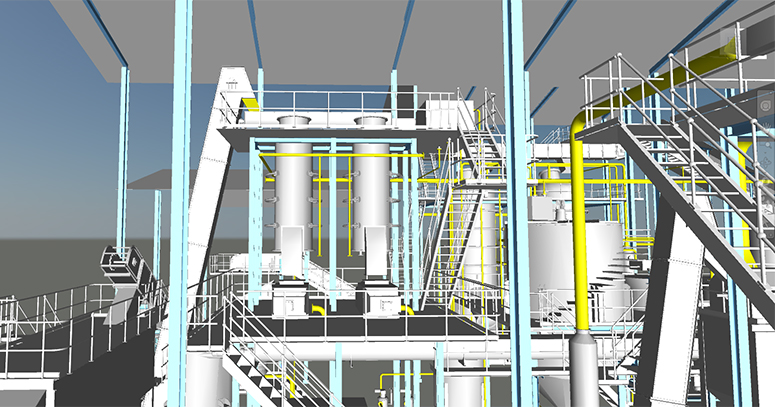

3D Plant Design

On the basis of plant layout design, combined with real situation, we can design a three-dimensional model of the entire plant. All the equipment, piping and instruments, any detail can be shown in the model, not only allowing you to have an intuitive understanding of the plant, but also providing overall information support for plant construction, equipment installation and future expansion.

Automatic Control System

We offer economical and most effective process automation solutions for the entire production line. Our RES automatic control system is developed based on PLC/DCS system.

Data Integration

From the perspective of the overall operation of the factory, Myande intelligent data integration management system collects basic data from raw grain procurement, warehousing, processing, inventory, sales and logistics, relying on the interconnection network system of each workshop. It provides real-time, accurate and traceable data reports for the current storage, processing and shipping.

Equipment Manufacturing

We owns in-house manufacture base of more than 120,000㎡ integrating R&D, production, project management which represents advanced engineering capability in the industry.

Installation and Commissioning

After finishing the installation of all machines, we offer on-site commissioning service to ensure compatible functioning.

Every move of the machine needs strong technical support from our experienced engineers. The only principle is that you can start manufacturing right after the commissioning.

Training and After-sales Service

Myande 360° Service Portfolio covers all your needs throughout the life cycle of your project. By minimizing your total cost of ownership, we help you stay ahead of the competition.

About Myande

Myande Group is a globally leading supplier of complete plants, equipment, and services for Oils & Fats, Starch & Derivatives, Fermentation, Evaporation & Crystallization, Material Storage and Handling and Smart Factory industries.

Myande Group currently has 1,000+ employees including 400 technical staff and 600 manufacturing workers. More than 1,000 complete plants have been supplied under Myande’s name in around 80 countries since 2003.

World-leading manufacturing base

In-house manufacture base of more than 130,000㎡ that integrates R&D, production, and project management, representing world-class engineering capability in the industry.

No Compromise on Quality

We are highly committed to Quality Assurance.

Our facilities and processes adhere to the highest local and international industry standards and certifications and are audited regularly for compliance.

With a global quality management system, we ensure that our customers all over the world receive high-quality, reliable products and solutions. We are well aware that our equipment have to function safely and efficiently for decades.

To effectively carry on the spirit of artisanship, improve the overall quality of front-line employees, we hold the “Workmanship Skills Competition" every year.

Certificates & Patents

At Myande, innovation is the result of the total process of developing an idea into a product or a new way of working which adds value to the business.

Over 400 registered patents and utility models demonstrate the company's innovation potential.

Our Global Presence

We focus on supplying one-stop engineering service covering general layout plan, process design, R&D, equipment manufacturing, automatic control system, data integration, installation, supervision, commissioning, training and etc.

Our custom solutions come from a deep understanding of your needs, and we have the capability to complete each project from the design of the initial concept to manufacturing, installation, commissioning and delivery.

You might also be interested in

Related Products

Lifecycle Service

Technical expertise and innovative products form the basis of your success. But we offer you even more: our extensive range of services gives you optimum support for your requirements and objectives in the long term.

Myande News & Insights

5,000TPD Oilseeds Crushing and 1,000TPD Oil Refining Line Commissioned

Recently, Chongqing Yide 5,000TPD oilseeds crushing and 1,000TPD oil refining production line was successfully put into operation and was accepted with excellent indicators. The production line has the characteristics of novel layout, advanced technology and innovative equipment. Integrating architectural aesthetics into modern factories Chongqing Yide Grain and Oil Co., Ltd. was established in 2020 and invested by Nantong Yide Investment Holdings Co., Ltd. Yide is not only a leading enterprise in Nantong, but also has been committed to the transformation to intelligence and environmental protection. The founders of the company have ultimate pursuit of quality. Myande design team has made a lot of attempts and innovations based upon the needs of customers, integrating architectural aesthetics into modern factories, making the buildings more beautiful, the layout more reasonable, and allowing industry and nature to co-exist in harmony. Globally unique logistics layout Chongqing Yide plant adopts a loop-shaped layout and design. Through bold innovation, it breaks through the concept of the traditional edible oil factory layout, making the factory look more like an architectural complex, not an edible oil plant. The layout of the loop-shaped factory is not only beautiful, but also the world's unique new logistics layout. Oilseeds pretreatment, extraction and refining plants are all designed in an integrated way, greatly reducing the space occupation and building height, making the layout more rational and compact, and the safety and construction cost of the whole project are well controlled. Innovation makes the dream come true In addition to the innovative factory layout, there are also many innovations in terms of equipment. Both sides have made many in-depth communication based on customer's original experience and newly proposed ideas. The technical and R&D team of Myande take the responsibility to realize the customer's dream and make a lot of attempts and innovations, which achieve good results and economic benefits. The core machines incorporated in the plant are all developed, designed and manufactured independently, such as the new-style Vertical Seed Conditioner, E-type Extractor, DTDC, Combined Type Deodorizer, Reclaim System and etc. In particular, the new-style Vertical Seed Conditioner has the characteristics of high heat transfer efficiency, small footprint and low steam consumption. The reclaim system for raw grain flat warehouse adopts a modular unitized design, with simple structure, high flexibility and efficient operation. Factory tour model boosts industrial tourism The value of a modern factory is not only reflected in its production and manufacturing, but also in the need to meet the trends of social development. Chongqing Yide has integrated industrial tourism and food safety and health education into the design of the factory at the beginning. When completed, Chongqing Yide will not only be a modern grain and oil processing enterprise, but also a training base for food safety and health education. While contributing to local economic development, it also enriches the lives of local people and adds an attraction for industrial tourism visits. Intelligence to improve operational efficiency Myande has been involved in the grain and oil processing industry for twenty years, and the technology has been continuously precipitated and iterated through project practice. In the construction of Chongqing Yide project, Myande adopted a large number of modern and intelligent control systems, which have improved the level of automation control and data integration of the whole plant, providing basic and objective technical data to improve the operation and management of the modern plant, as well as providing technical support for the digital transformation and intelligent manufacturing of the plant. In addition, various key process control points have also been optimized and upgraded to ensure more stable operation of equipment and more competitive product quality and energy consumption indicators. The completed Chongqing Yide plant will be a modern factory with low consumption, environmentally friendly, high technology and intelligence, as well as a key pivot point of Yide Group's strategic layout of agricultural products processing, bearing the important task of increasing the scale of oilseed processing and expanding the radiation radius of finished products. With nearly 20 years of experience in grain and oil processing industry, Myande is committed to being a value-creating company by providing intelligent, digital, sustainable and innovative solutions for our customers. Myande team are willing to work together with industry partners to help the development of a healthy, safe and intelligent industry.

Let Performance Speak

In 2011, the 6,000TPD soybean crushing plant was built by Myande Group for Guangxi Huiyu Grain and Oil Industrial Co.,Ltd, won First Prize of Science and Technology Awarded by Chinese Cereals and Oil Association. Since then, Myande Group has undertaken more than 10 crushing lines with capacity of 5,000TPD or over, each of which has stable operation, excellent product specifications and low energy and steam consumption. The product stability is inseparable from the systematic design and installation, but also from the core equipment of high performance. All the projects undertaken by Myande have adopted the Vertical Conditioner, Cracker, Flaker, Loop Chain Conveyor, Wet Meal Conveyor, Hot Meal Conveyor, Extractor, DTDC, Evaporator and Condenser developed independently by Myande. These equipment have conducted long test running by multiple projects, and their structure, operability and maintainability are constantly updated, by adopting excellent industry experience and precise data analysis, the performance indicators of equipment have been well-received by the majority of users. Cracker and Flaker: Mature and Stable, Maximum Benefits More than 200 units of Myande flakers and crackers are currently running at various prestigious oils & fats processing enterprises. Since they were put into the market in 2008, they have experienced long running tests, the stability and quality have been fully proved. In addition, they have been upgraded constantly along with the technology development. World-class core components from Europe and Myande’s sophisticated manufacturing facility combine to guarantee their reliability and excellent performance. Loop Chain Conveyor: Energy Efficient, Stable and Reliable With the obvious tendency of increasing capacity of oil seeds crushing lines, compact equipment layout scheme and smooth & reliable material logistics inside the crushing plants has received high priority. Thus, loop chain conveyors have been widely used in the large oils & fats processing projects. “Loop” layout of conveyor has provided a more efficient and integrated process design, with simplified feeding and discharging devices enabling multipoint feeding and discharging. Its stable operation and superior performance have been highly evaluated by the customer. Myande Loop Conveyors have ended monopoly of similar type of conveyors by foreign suppliers. At the moment, 30 sets of Myande loop chain conveyors are running stably. Horizontal Rotary Cooker: High Efficiency, Low Consumption As the processing capacity of oils & fats industry expands gradually, power consumption has attracted increasing attention. Horizontal rotary cooker has gradually replaced the old vertical cooker. Horizontal rotary cooker represents new processing technology, improves the processing capacity greatly, and reduces energy consumption. Myande’s horizontal rotary cooker features U-shape screw conveyor feeding, siphoning discharging and stepless speed regulation. These features facilitate sufficient material heating and have much lower energy consumption. Now, 35 sets of Myande’s horizontal rotary cookers are running stably. Wet Meal Conveyors and L-shaped Drag Conveyors: High Efficiency and Easy Operation Myande’s wet meal conveyors and L-shaped conveyors are high-performance lifting & conveying equipment with optimized design on the basis of the characteristics of vegetable oil processing.Their patented no-reverting structure greatly improves conveying efficiency. On the other hand, by using high-strength wear-resistant plate, Myande wet meal conveyors and L-shaped drag conveyors feature longer service life and higher reliability. Currently, Myande’s wet meal conveyors and L-shaped conveyors are running in over 100 crushing lines, including 9 crushing plants with capacity of 5,000TPD and above. The stable operation and excellent performance are well received by the customers.

5 Reasons to Choose Myande Flakers

Since 2009, Myande Flakers have been widely used by oil and fat processing companies around the world. More than 250 units are currently in operation. After long-term operation and continuous improvement, the excellent performance and reliable quality of Myande flakers have been highly trusted by customers all over the world. 1. Excellent Flaking Effect The advanced and reliable roll-spacing adjustment mechanism and patented roll-end anti-leakage system ensure that the thickness of flakes is uniform, which is conducive to the control of residual oil in extracted cake. 2. More Energy-efficient The advanced hydraulic automatic tensioning system ensures that the main driving and driven systems always maintain the best tension of the transmission belt to improve the transmission efficiency. Excellent manufacturing and assembly can minimize the vibration of flaker to greatly reduce the loss. After being used and certified by authoritative users, the electricity consumption per ton of material is at the international leading level. 3. Lower Maintenance Cost Myande intelligent manufacturing system ensures excellent quality, including laser cutting, robot welding, pentahedron processing, surface treatment, and precision assembly. The advanced structure and intelligent manufacturing have greatly reduced the failure rate and made the maintenance cost of Myande flaker at a lower level. 4. Intelligent Control System Myande flaker is equipped with complete intelligent control system to realize human-computer interaction. And the communication system is available to realize remote control and unmanned operation, which can reduce labor cost. 5. Highly Recognized by World's Leading Oil Seeds Crushers Myande flaker has been widely used by many large oil manufacturers in China and has become a high-quality key equipment for them. What's more, Myande flaker has been adopted by more and more top international large oil manufacturers. Myande adheres to the mission of "With professionalism, we manufacture high quality mechanical products and supply complete solutions that enable our clients to succeed. We are dedicated to create a bright future for us as well as for our clients.", and is committed to becoming the world's top manufacturer of flaker and creating value for customers.

Main Factors Affecting Residual Oil Content in Soybean Meal

Residual oil content in soybean meal is an important indicator during the production process of soybean oil processing factories, which reflects the level of production, management and technology of the enterprise. And it is one of the key issues concern by oils & fats processing enterprises. In this article, several factors affecting residues oil content in soybean meal are specifically analyzed, and corresponding suggestions were presented in accordance with the production practice, to reduce the residual oil in soybean meal and improve economic efficiency. With the development of edible oil industry, soybean crushing plants are changing with each passing day, and the application of various new technologies, new equipment and new processes has gradually increased the scale of production. The control requirements for product indicators are also getting higher and higher, among which residual oil content in soybean meal has received much attention as an important indicator in the extraction process. The residual oil content in soybean meal refers to the content of oil that has not been extracted from soybean meal after the preparation section and solvent extraction section. It is of great economic significance to reduce the residual oil content in soybean meal. For example, estimated by the crushing capacity of 3,000 tons per day, if residual oil content in soybean meal is reduced by 0.1%, it will increase the profit of more than 100,000 dollars for soybean oil processing enterprises every year. At the same time, the amount of residual oil in soybean meal also reflects the level of processing technology and production management, and indirectly demonstrates the differentiated competitiveness among enterprises. Therefore, it is highly valued by soybean oil processing enterprises. 1. Pretreatment Section Pretreatment includes several steps such as cleaning, soybean conditioning, cracking and dehulling, flaking, extrusion, etc., which are closely related, and each process adjustment will affect the next process. 1.1 Cleaning Soybean maybe mix with a certain amount of impurities during harvesting, transportation and storage. These impurities are mainly straw, stems and leaves, soil, metal objects, etc. The purpose of this section is to remove impurities from the oilseed. If these impurities are not removed, on the one hand, the impurities will adsorb a certain amount of oil and remain in the cake, thereby reducing the oil extraction efficiency. On the other hand, impurities will be carried to the next section, affecting the processing effect of other sections. For example, the inclusion of iron in the raw material will not only affect the cracking and flaking effect, but also shorten the service life of the equipment and even damage the equipment. 1.2 Conditioning The soybean hull is thin and has strong binding force with the seed kernel. Even broken under the action of external force, the hull may still adhere to the broken kernel, and it is difficult to be completely removed. The conditioner can regulate the moisture and temperature of soybean, which reduces the moisture content of soybean by 1% to 2%, and raises the temperature to 55-65 °C, so that the soybean hull becomes crisp and easy to crack. After the subsequent cracking, dehulling is easier and the efficiency is higher. 1.3 Cracking After the cracking section, the soybeans are broken into 6-8 petals with relatively uniform size, and soybean hulls are easily detached from the surface of the beans. If the bean hull is not removed, it is easy to absorb oil during the extraction section, which leads to an increase of residual oil in soybean meal. In addition, in the large-scale edible oil production, the removal of more than 80% of bean hull can greatly improve the processing capacity of the equipment, so it is necessary to use the aspirator for dehulling after cracking. The soybean hull content is 6%-8%, and the oil content in the soybean hull is generally less than 1%. The main component of the soybean hull is cellulose. If the dehulling is insufficient, part of the bean hull will adhere to the surface of the flakes after flaking, thus forming an isolating membrane which can hinder the direct contact between solvent and oil in the bean kernel when extracting. This is not conducive to oil extraction and will result in an increase of residual oil in soybean meal. On the contrary, if soybeans are fully dehulled, the above drawbacks can be overcome. 1.4 Flaking The flaking process is to squeeze the oilseed cells against each other by the pressure between the flaking rolls. So that part of the cell walls are destroyed, and the oilseed turn into thin flakes with large surface area. Thereby the flaking process can shorten the path of oil extracting from oilseed. In theory, the larger the surface coefficient of the contact between the flakes and solvent, the better the extracting effect. If the flake is too thin (<0.3 mm), the powder degree will increase, which will affect the cyclical penetration of the miscella, eventually causing the residual oil content in soybean meal to increase. If the flake is too thick (>0.5 mm), the cell tissue will not be completely destroyed. The solvent cannot be quickly penetrated into the interior of the flakes, and the oil inside the flakes cannot be rapidly diffused outward. Therefore, the thickness of flakes should be checked frequently during the production process, and the thickness of flakes should be 0.3-0.4 mm. 1.5 Extrusion/ Expansion The expanded oilseed flakes have good porosity and permeability, and the permeation rate of the miscella is significantly improved. The amount of penetrative miscella per square meter per hour can reach 40-50 cubic meters. Therefore, good permeability can cause the residual oil rate to decrease accordingly. After the expansion, the solvent is not easily retained when the flakes run to the leaching section of the extractor. So the load of the solvent recovered by the desolventizer and drying system is reduced, and the heat and steam consumption are also reduced. In the actual production process, parameters such as moisture, expansion temperature, and steam volume should be adjusted to ensure the best expanding effect. 2. Extraction Section During the extraction process, the factors affecting the residual oil content in soybean meal are extracting temperature, extracting time, the purity of solvent, and the amount of solvent. 2.1 Extracting Temperature The solvent used in the current extraction industry is mainly n-hexane, and its distillation range is 66-68 °C. The extracting temperature is preferably in the range of 55-60°C, in which case the thermal movement of the solvent and oil molecules is relatively strong. The viscosity is relatively low and the diffusion resistance of the solvent and oil molecules is small. However, if the extracting temperature is too high, on the one hand, a large amount of vaporization of the solvent will occur, which will not only increase the condenser load, but also cause insufficient extracting and increase the residual oil content in spent meal. On the other hand, solvent accelerates the dissolution of non-greasy substances such as phospholipids, sugars, colloids, pigments, etc. Too high extracting temperature can also affect the color of soybean meal. Conversely, if the extracting temperature is too low, the viscosity of the solvent and oil becomes high and the thermal movement is weakened. The diffusion resistance of the solvent and oil molecules increases, eventually leading to a decrease in the extracting rate. 2.2 Extracting Time The longer the extracting time, the lower the residual oil in the soybean meal. At the beginning of the extracting stage, the oil content in the cake/flake will decrease rapidly and then slowly decrease. To ensure productivity, a long-time extracting is not realistic. Whether the extracting time is reasonable or not depends on the characteristics of the input material, the extracting temperature and the type of extractor. Under the premise of ensuring the ideal residual oil index, the extracting time is shortened as much as possible in order to increase the production capacity and reduce the production cost. 2.3 Purity of Solvent During the extracting process, it is important to ensure that the solvent is pure. In general, there are two main reasons for causing the solvent to be impure: ① The evaporator is flooded, causing the solvent to carry oil into the water separation tank. After the water is separated, the solvent turns yellow, so that the solvent is not pure. ② The positive pressure of the water separation tank is too large, causing the solvent to mix with water. Mixing oil or water in the solvent will reduce the effect of the last fresh solvent spray. To ensure the purity of fresh solvent, the following technical measures should be taken: ① Ensure that the steam pressure used in production process is stable, and keep the evaporator working within the specified temperature and vacuum range. ② Increase the effective volume of the water separation tank to enhance the water separation effect. 2.4 Amount of Solvent The amount of solvent is usually measured by the solvent ratio, which is the ratio of the mass of the solvent used per unit time to the mass of the extracted material. The large solvent ratio has a certain effect on reducing the residual oil in soybean meal, but the concentration of the miscella is lower, which increases the load on the evaporation system and the solvent recovery system. So the steam consumption is larger. The small solvent ratio, that is, the amount of fresh solvent is reduced, and the concentration of miscella increased, so the driving force of the mass transfer process is insufficient, resulting in incomplete extracting and high residual oil in soybean meal. Therefore, it is important to choose a reasonable solvent ratio under the premise of ensuring residual oil index. 3. Conclusion By analyzing each step of the pretreatment section and extracting section, there are many factors affecting the residual oil content in soybean meal. These factors are complicated and mutually influential. The operator should make a targeted analysis according to the actual production situation, and make timely adjustments to reduce the residual oil content in soybean meal and improve the economic benefits of the enterprise.

Impact of "Carbon Neutrality" on Edible Oil Industry

What is carbon neutrality? Carbon neutrality means having a balance between emitting carbon and absorbing carbon from the atmosphere in carbon sinks. Removing carbon oxide from the atmosphere and then storing it is known as carbon sequestration. In order to achieve net zero emissions, all worldwide greenhouse gas (GHG) emissions will have to be counterbalanced by carbon sequestration. The main culprit behind floods, droughts, extreme cold and heat waves, and melting glaciers are greenhouse gases emitted by human activities, which have caused global warming to intensify and pose a huge threat to the earth. So it is imperative to take action. UN member states have reached a consensus to achieve global "carbon neutrality" between 2050 and 2100. A growing number of countries have announced timelines for achieving carbon neutrality. China also clearly stated in 2020 that it would achieve carbon neutrality by 2060. Edible oil industry and "carbon neutrality" In order to achieve the goal of carbon neutrality and zero emissions, countries have begun to carry out energy transformation: gradually reduce the use of fossil energy such as coal and oil, and shift to wind power, solar energy, biomass and other low-carbon clean energy. Soybean oil, palm oil, canola oil and other vegetable oils can be used to produce biofuels, so vegetable oil is no longer just for human consumption, cars, airplanes, ships, etc. also "drink" vegetable oil. Indonesia, the largest producer and exporter of palm oil, mandates a 30% blend of palm oil (B30) in diesel in 2020 and plans to increase to B40. Malaysia plans to complete a national B20 biodiesel program by 2022. The United States has clearly proposed a clean energy plan and focus on the application of biomass liquid fuels. More and more soybean oil in the United States is used to make biodiesel, which has accounted for about 40% of the total consumption of soybean oil. Although the mandatory biodiesel blending policies of various countries have been repeated from time to time, the industrial demand for vegetable oil is rising in the context of global "carbon neutral", accounting for about 30% of the total global demand for vegetable oil, and it is difficult to reverse the direction of advancement. Industry giants are looking to the wind and have set off a wave of entry into the biofuel market. Since 2021, international grain merchants such as ADM, Bunge and Cargill, international energy giants such as ExxonMobil, Marathon Oil and Chevron, and even international food giants including Nestle, have increased their bets on the biofuel sector. They build and expand new soybean, rapeseed and other oilseeds crushing plants, or renovate traditional oil refineries, or join hands with joint ventures to produce renewable diesel. As the scale of biofuel processing capacity continues to expand, giant producers are bound to compete fiercely around feedstock including vegetable oils, thus becoming an important variable affecting the supply and demand pattern of oils and fats. The raw material side of the edible oil market may experience more thrilling ups and downs. Edible oil producers and "carbon neutrality" For edible oil producers, "carbon neutrality" means that the traditional industrial era is coming to an end, but also means the advent of a green development approach and a possible trend of low-carbon food consumption. In the future, regardless of the size of enterprises, they will have to set carbon emission reduction targets and design carbon emission reduction initiatives, even affecting bank loans, because banks also have the task of "green finance" to reduce emissions. In July 2021, the UN Global Compact released the report "Corporate Net Zero Pathway", which recommends that companies in all industries develop net-zero transition programs based on nine key initiatives. Food products need to go through R&D, harvesting, processing, distribution, retail, storage and other links before being put on the table. Each link generates greenhouse gases. Therefore, the carbon emission reduction of food manufacturers, including edible oil producers, includes: reducing carbon emissions in the manufacture process, reducing packaging complexity, switching to recyclable materials, and reducing carbon emissions in the transportation and distribution of raw materials and products. China's leading edible oil manufacturers have already begun the practice of "carbon neutrality". In 2020, 88% of the energy needs of COFCO International's global operations has been met by renewable energy and carbon emissions has been reduced by 4% overall. Yihai Kerry has adopted green development measures, such as building a solar photovoltaic system on the roof of an existing factory building, to reduce carbon emissions and reap economic benefits. Low-carbon food development will also be a new opportunity. Low-carbon food is food that consumes less energy and emits less greenhouse gases during its life cycle (from the processing of raw materials to the consumption), while the opposite is high-carbon food. In a word, "carbon neutrality" has risen to the level of global strategy, and the driving force of green technology and low-carbon food industry innovation is bound to strengthen. In order to avoid lagging behind in the transition to a green economy, edible oil manufacturers should plan early for "carbon reduction" goals such as circular economy, green energy, and zero-carbon factories, and start putting them into practice. View more on LinkedIn

Impact of "Carbon Neutrality" on Edible Oil Industry

What is carbon neutrality? Carbon neutrality means having a balance between emitting carbon and absorbing carbon from the atmosphere in carbon sinks. Removing carbon oxide from the atmosphere and then storing it is known as carbon sequestration. In order to achieve net zero emissions, all worldwide greenhouse gas (GHG) emissions will have to be counterbalanced by carbon sequestration. The main culprit behind floods, droughts, extreme cold and heat waves, and melting glaciers are greenhouse gases emitted by human activities, which have caused global warming to intensify and pose a huge threat to the earth. So it is imperative to take action. UN member states have reached a consensus to achieve global "carbon neutrality" between 2050 and 2100. A growing number of countries have announced timelines for achieving carbon neutrality. China also clearly stated in 2020 that it would achieve carbon neutrality by 2060. Edible oil industry and "carbon neutrality" In order to achieve the goal of carbon neutrality and zero emissions, countries have begun to carry out energy transformation: gradually reduce the use of fossil energy such as coal and oil, and shift to wind power, solar energy, biomass and other low-carbon clean energy. Soybean oil, palm oil, canola oil and other vegetable oils can be used to produce biofuels, so vegetable oil is no longer just for human consumption, cars, airplanes, ships, etc. also "drink" vegetable oil. Indonesia, the largest producer and exporter of palm oil, mandates a 30% blend of palm oil (B30) in diesel in 2020 and plans to increase to B40. Malaysia plans to complete a national B20 biodiesel program by 2022. The United States has clearly proposed a clean energy plan and focus on the application of biomass liquid fuels. More and more soybean oil in the United States is used to make biodiesel, which has accounted for about 40% of the total consumption of soybean oil. Although the mandatory biodiesel blending policies of various countries have been repeated from time to time, the industrial demand for vegetable oil is rising in the context of global "carbon neutral", accounting for about 30% of the total global demand for vegetable oil, and it is difficult to reverse the direction of advancement. Industry giants are looking to the wind and have set off a wave of entry into the biofuel market. Since 2021, international grain merchants such as ADM, Bunge and Cargill, international energy giants such as ExxonMobil, Marathon Oil and Chevron, and even international food giants including Nestle, have increased their bets on the biofuel sector. They build and expand new soybean, rapeseed and other oilseeds crushing plants, or renovate traditional oil refineries, or join hands with joint ventures to produce renewable diesel. As the scale of biofuel processing capacity continues to expand, giant producers are bound to compete fiercely around feedstock including vegetable oils, thus becoming an important variable affecting the supply and demand pattern of oils and fats. The raw material side of the edible oil market may experience more thrilling ups and downs. Edible oil producers and "carbon neutrality" For edible oil producers, "carbon neutrality" means that the traditional industrial era is coming to an end, but also means the advent of a green development approach and a possible trend of low-carbon food consumption. In the future, regardless of the size of enterprises, they will have to set carbon emission reduction targets and design carbon emission reduction initiatives, even affecting bank loans, because banks also have the task of "green finance" to reduce emissions. In July 2021, the UN Global Compact released the report "Corporate Net Zero Pathway", which recommends that companies in all industries develop net-zero transition programs based on nine key initiatives. Food products need to go through R&D, harvesting, processing, distribution, retail, storage and other links before being put on the table. Each link generates greenhouse gases. Therefore, the carbon emission reduction of food manufacturers, including edible oil producers, includes: reducing carbon emissions in the manufacture process, reducing packaging complexity, switching to recyclable materials, and reducing carbon emissions in the transportation and distribution of raw materials and products. China's leading edible oil manufacturers have already begun the practice of "carbon neutrality". In 2020, 88% of the energy needs of COFCO International's global operations has been met by renewable energy and carbon emissions has been reduced by 4% overall. Yihai Kerry has adopted green development measures, such as building a solar photovoltaic system on the roof of an existing factory building, to reduce carbon emissions and reap economic benefits. Low-carbon food development will also be a new opportunity. Low-carbon food is food that consumes less energy and emits less greenhouse gases during its life cycle (from the processing of raw materials to the consumption), while the opposite is high-carbon food. In a word, "carbon neutrality" has risen to the level of global strategy, and the driving force of green technology and low-carbon food industry innovation is bound to strengthen. In order to avoid lagging behind in the transition to a green economy, edible oil manufacturers should plan early for "carbon reduction" goals such as circular economy, green energy, and zero-carbon factories, and start putting them into practice. View more on LinkedIn

Follow Myande, Rediscover the Cottonseed Oil

Cottonseed oil is also called cotton oil for short, it has been used as an edible oil in China for thousands of years. In fact, cottonseed oil is still a mainstream cooking oil all around the world. Cotton oil is a mainstream edible oil. Cotton oil is a type of oil made by pressing cotton seeds and further refining. China is the world’s largest producer of cotton and cottonseed, producing 9.2 million tons of cotton seed and around 1.3 million tons of cotton oil in 2021, followed by India, the USA, Brazil, Pakistan and Uzbekistan. Xinjiang, Huanghuai River basin and Yangtze River basin are the top 3 cotton-producing regions in China. In Hebei, Shandong, Henan, Xinjiang and other places where cotton is grown, cotton oil is the traditional cooking oil for local people. And cotton oil processing plants are mainly concentrated in the north-west, north and east China. Cotton oil also has a certain of share in the international vegetable oil market and is still widely consumed in USA, Canada, Europe and other developed countries. Cottonseed oil contains nearly 80% unsaturated fatty acids and is also rich in functional ingredients such as vitamin E, sterols and squalene, as well as being resistant to high temperatures and antioxidants, making it more suitable for frying. A number of well-known foreign restaurant chains use cotton seed oil as the first choice of frying oil. Why is cottonseed oil rarely promoted? Since the cottonseed oil has high quality and high consumption, why it is rarely promoted? Because there has been controversy over the use of cottonseed oil, and the price can’t be matched with the value, the industry development has encountered difficulties. Gossypol is a natural ingredient to resist pests and diseases contained in cotton, but it is harmful to humans. In the past, restricted by production technology, unrefined cotton oil contains gossypol and other harmful substances, and there have been food safety incidents caused by the consumption of unrefined cotton oil. As a result, people still have a prejudice against cottonseed oil. Nowadays, cotton oil has been refined to remove harmful substances and is safe for consumption, but the public cannot distinguish between the concepts of crude cotton oil and refined cotton oil. There are also a lot of vague media reports that not only do not clear up people's doubts, but also add to the misconceptions about cottonseed oil. When we search for information on cottonseed oil, most of the information is negative. However, what the public does not understand is that China's cottonseed oil and cottonseed processing comprehensive utilization technology is already in the international leading position. Myande Group has developed the dephenolization technology to effectively remove the gossypol contained in cotton oil and cottonseed protein. In addition, cottonseed protein can replace soybean meal for the feed industry, and cottonseed hulls are the main raw material for culture medium in edible mushroom industry, thus making the best use of cottonseed resources. Find the right position and follow the trend. The current edible oil market is highly competitive, but the seemingly saturated edible oil market can still be subdivided into categories. For example, peanut oil, corn oil and tea seed oil all have taken their place in their respective market segments and created good reputation and economic benefits. Nowadays, cottonseed oil is mostly used as a raw material for blending oil, and is often "anonymous". Cottonseed processing enterprises should be based on the characteristics of cottonseed oil, find the right market positioning, dig deeper into the value of the product, to obtain profit and market space.

2,000TPD Rapeseed Crushing Plant Launched

Recently, a 2,000 t/d rapeseed crushing plant built by Myande Group for Daodaoquan Grain and Oil Co., Ltd. started operation successfully and started to yield qualified rapeseed oil and meal. Daodaoquan Grain and Oil Co., Ltd. is a comprehensive oil processing enterprise integrating production, scientific research, trade, warehousing and logistics of edible vegetable oil and its related by-products. This new rapeseed crushing plant incorporates a wide range of Myande core equipment possessing independent intellectual property rights, including the E-type extractor, hydraulic flaker, DTDC, conditioner, and other key equipment. To achieve flexible material incoming and discharging, Myande CCJL series sweep auger and CQJL series reclaimer are used. In addition, advanced energy-saving technology, negative pressure draining technology and intelligent safety technology are used to ensure the stable operation of the entire production line and excellent product index. With the concept of "creating the best performance for our customers", Myande cooperates with DaoDaoQuan to build a modern, energy-efficient, and environmentally friendly factory.

600,000 T/A Wheat Starch Deep Processing Project Successfully Launched

Recently, the 1st phase of Henan Hanyong's 600,000 tons (annual output) wheat starch deep processing project, designed by and installed under the guidance of Myande, has been smoothly commissioned, and contract for the 2nd phase was signed with Myande, marking the further extension of the domestic wheat deep processing industry chain. Henan Hanyong Biotechnology Co., Ltd. is one of the leading enterprises in agricultural industrialization of Henan province. It mainly produces edible alcohol with strong competitiveness and a high reputation in the market. Starch deep processing is one of Myande’s important business segments. After years of technology and experience accumulation in the field of starch deep processing, Myande has formed a complete set of production design system with a high degree of automation, stable operation and high product quality. In recent years, Myande has successfully established long-term strategic cooperative relations with multiple famous domestic and international enterprises. Combining with Hanyong's own industrial advantages, after in-depth research, efficient communication and repeated demonstrations, Myande has designed a set of production plan (as shown in the following figure) specially for the customer, and it can not only produce gluten and wheat starch, but also make better use of the mixed nutrient solution of process water and pentosan to produce alcohol, which will bring considerable economic benefits. The 1st phase project is a 500tpd wheat flour processing project, including a 3tpd gluten drying system and a 12tpd starch drying system. From beginning to end, the whole project lasted for 10 months. During the whole implementation process, from the plant layout planning, process design, intelligent automation design in the early stage, project service in the mid-term, to the installation, commissioning and training in the post stage, Myande’s rigorous, attentive and efficient one-stop service has won the unanimous praise of Hanyong. Through the joint efforts of Myande and Hanyong employees, a brand-new starch deep processing production line was successfully commissioned and started running smoothly, and all indicators were superior to the technical level of the same industry. In view of the pleasant cooperation in the 1st phase, Hanyong decided to cooperate with Myande again to expand its wheat starch deep processing output, and signed the 2nd phase project with Myande resolutely, namely 5t/d gluten drying system and 20t/h starch drying system. After which, Hanyong will become a high-quality gluten high-value conversion base with "the largest scale, the best environment protection and the highest level of research and development" in the industry in Asia.

Myande Awards 2022 “Spring Sunshine” Scholarship

In order to motivate employees' children to study hard and to enhance employees’ sense of belonging and happiness, on August 19, Myande held 2022 Myande Spring Sunshine Education Scholarship ceremony. Mr. Wangmu, vice chairman and Mr. Mao Weijiang, director in charge of manufacturing, participated in this ceremony and on behalf of the company presented scholarship stipends to children of Myande employees who are enrolled by four-year universities this year. In his speech, Mr. Wang highlighted that Spring Sunshine Scholarship is one of several company welfare benefits. It represents the company’s vision of moving forward with its employees and creating a better future together, and it reflects the company's care for the education of its employees' children and its high sense of social responsibility.

Contact Us

Contact us to see how we can help you grow your business.

Find the solution to an optimized future.