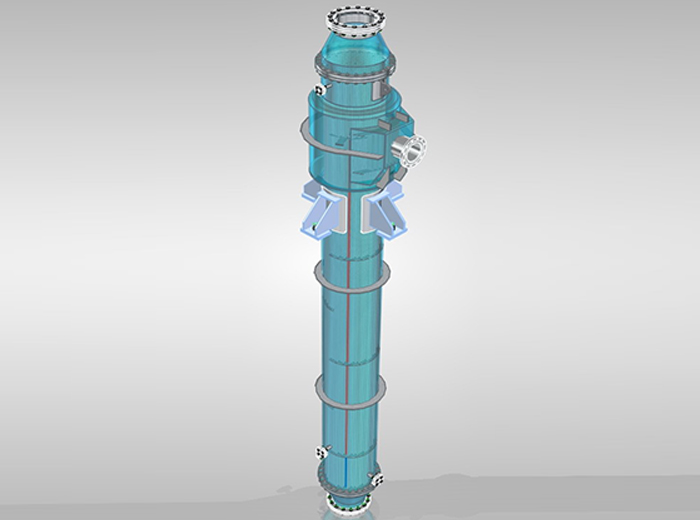

Forced Circulation Evaporator

As raw material (liquid) circulates among heating and separation chambers at a high speed under the function of a circulating pump, it is heated up in the heating chamber and flashes in the separation chamber to achieve high-efficiency vapor-liquid separation. The flow rate in the heat exchange tube is high, which effectively improves the heat transfer efficiency. The evaporation process is conducted in the separator instead of heater. As a result, fouling caused by crystallization and precipitation of materials in the tubes is reduced. Forced circulation evaporator is especially suitable for materials that are easy to scale due to high viscosity, and can be used as a high-efficiency concentration device for multi-effect evaporation.