Solid-state Fermentation

Unlocking the Nutritional Power of Feed through Solid‑State Fermentation

In 2024, global demand for high‑quality animal feed additives reached over USD 60 billion, driven by a shift to sustainable protein and enhanced feed efficiency. Solid‑state fermentation (SSF) of oilseed meals and agricultural by-products improves digestibility and delivers 10–30% higher nutritional value compared to untreated meals. However, many feed manufacturers face challenges: lack of turnkey solutions, poor process control, variable yields, and complex pilot‑to‑plant scaling.

Enter Myande — with 20+ years of delivering fully integrated SSF solutions, we partner with global feed & edible‑oil leaders to tailor turnkey plants from concept to after‑sales. Our precise 3D design and automation guarantee consistent, scalable results — so your facility can meet rising demand with confidence.

Animal Feed Materials Fermentation

Using biological fermentation technology, the anti-nutritional factors in protein raw materials such as soybean meal, cottonseed meal, rapeseed meal, palm meal and rice bran meal can be removed to improve the digestibility of protein, increase the metabolites and the value of protein. The fermentation process can be classified as anaerobic fermentation, aerobic fermentation and facultative fermentation according to the characteristics of the strain.

Myande has developed a series of patented fermentation equipment for different fermentation processes, while customers can choose the right drying equipment according to different drying needs.

Agricultural By-product Fermentation

The by-products of flour mills, starch mills and other food processing factories can be used as raw materials, such as bran, corn fiber, corn protein, rice protein and distilled grain, to produce fermented products using biological fermentation technology to enhance the added value of agricultural by-products, which can be better applied in the feed industry.

Yeast Culture Fermentation

Corn flour and protein powder are used as raw material medium, and after sterilizing, solid state fermentation is carried out with yeast as the strain, and yeast metabolites and yeast protein are obtained by low temperature drying after the fermentation.

Jiuqu Fermentation

Bran and rice husk are used as raw material, and after cooking, sterilizing and cooling, solid state fermentation is carried out with aspergillus, yeast as the strain to produce products containing metabolites such as protease, cellulose and yeast cultures, which are used for baijiu (Chinese liquor) factory.

Solid-state Bio-enzyme Fermentation

After sterilizing and cooling, bran, soybean meal and other raw materials as the medium, solid-state fermentation is carried out with aspergillus and bacillus as the strain, to produce protease, cellulase and other metabolites. The process features controlled fermentation environment, high degree of automation and stable products.

Bran Fermentation

Bran is used as raw material to produce protease and cellulase using aerobic or anaerobic fermentation process, or culturing aspergillus and bacillus. Lactic acid bacteria anaerobic fermentation can also be adopted to produce fermented feed.

Solution Tailored to Your Needs

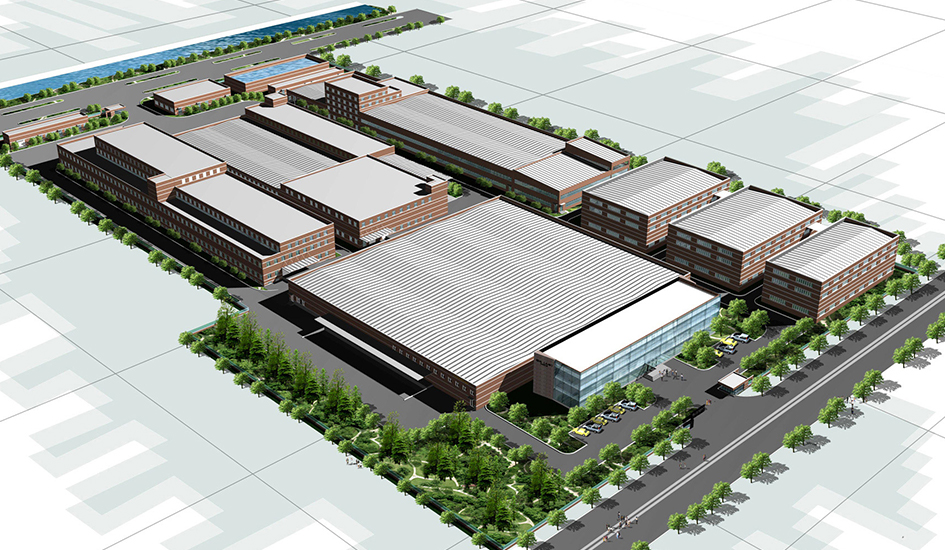

General Layout Plan

With a land prepared, the next thing you should consider is planning the general layout, which is a crucial foundation of a sustainable and cost-effective manufacturing.

Turn to us for help and we will present you the design for your plant by considering water, steam, electricity supply and etc.

Process Design

Combining our engineering expertise, industry know-how and practical skills with your knowledge, we provide the optimized and customized process design for your plant.

3D Plant Design

On the basis of plant layout design, combined with real situation, we can design a three-dimensional model of the entire plant. All the equipment, piping and instruments, any detail can be shown in the model, not only allowing you to have an intuitive understanding of the plant, but also providing overall information support for plant construction, equipment installation and future expansion.

Automatic Control System

We offer economical and most effective process automation solutions for the entire production line. Our RES automatic control system is developed based on PLC/DCS system.

Data Integration

From the perspective of the overall operation of the factory, Myande intelligent data integration management system collects basic data from raw grain procurement, warehousing, processing, inventory, sales and logistics, relying on the interconnection network system of each workshop. It provides real-time, accurate and traceable data reports for the current storage, processing and shipping.

Equipment Manufacturing

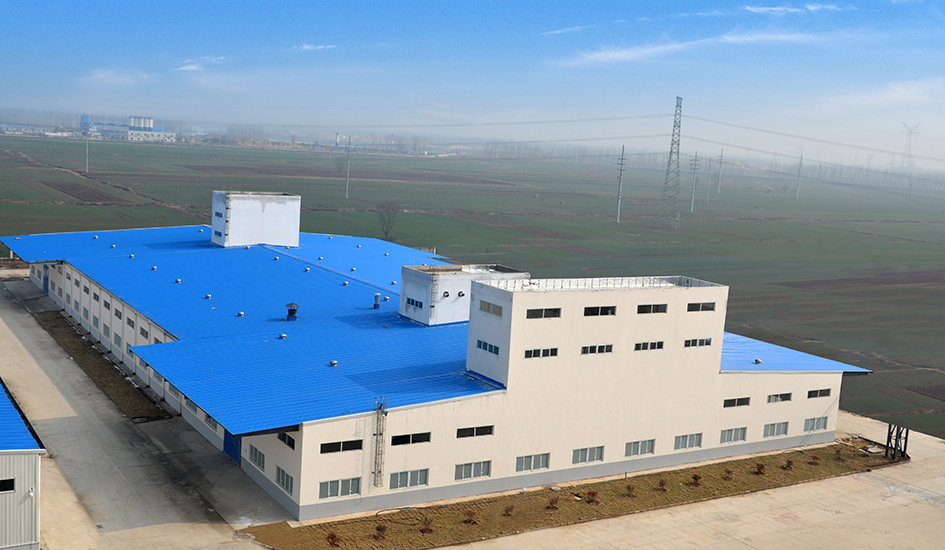

We owns in-house manufacture base of more than 130,000㎡ integrating R&D, production, project management which represents advanced engineering capability in the industry.

Installation and Commissioning

After finishing the installation of all machines, we offer on-site commissioning service to ensure compatible functioning.

Every move of the machine needs strong technical support from our experienced engineers. The only principle is that you can start manufacturing right after the commissioning.

Training and After-sales Service

Myande 360° Service Portfolio covers all your needs throughout the life cycle of your project. By minimizing your total cost of ownership, we help you stay ahead of the competition.

About Myande

Myande Group is a globally leading supplier of complete plants, equipment, and services for Oils & Fats, Starch & Derivatives, Fermentation, Evaporation & Crystallization, Material Storage and Handling and Smart Factory industries.

Myande Group currently has 1,300+ employees including 600 technical staff and 700 manufacturing workers. More than 1,200 complete plants have been supplied under Myande’s name in over 80 countries since 2003.

World-leading manufacturing base

In-house manufacture base of more than 130,000㎡ that integrates R&D, production, and project management, representing world-class engineering capability in the industry.

No Compromise on Quality

We are highly committed to Quality Assurance.

Our facilities and processes adhere to the highest local and international industry standards and certifications and are audited regularly for compliance.

With a global quality management system, we ensure that our customers all over the world receive high-quality, reliable products and solutions. We are well aware that our equipment have to function safely and efficiently for decades.

To effectively carry on the spirit of artisanship, improve the overall quality of front-line employees, we hold the “Workmanship Skills Competition" every year.

Certificates & Patents

At Myande, innovation is the result of the total process of developing an idea into a product or a new way of working which adds value to the business.

Over 500 registered patents and utility models demonstrate the company's innovation potential.

Our Global Presence

We focus on supplying one-stop engineering service covering general layout plan, process design, R&D, equipment manufacturing, automatic control system, data integration, installation, supervision, commissioning, training and etc.

Our custom solutions come from a deep understanding of your needs, and we have the capability to complete each project from the design of the initial concept to manufacturing, installation, commissioning and delivery.

You might also be interested in

Related Products

Lifecycle Service

Technical expertise and innovative products form the basis of your success. But we offer you even more: our extensive range of services gives you optimum support for your requirements and objectives in the long term.

Myande News & Insights

100TPD Soybean Meal Fermentation Project

In July 2016, a soybean meal fermentation line supplied by Myande Group for Zhejiang Cofine Biotech Inc. Ltd was put into production. It is expected that the successful completion of this project will accelerate Cofine’s pace of strategy development and enhance Myande’s market recognition in the solid fermentation engineering industry. It represents one milestone in Myande’s achievements in accelerating sustainable and healthy development of green animal feed industry. Initiated by Dr. Zhang Tingzhou, Zhejiang Cofine Biotech Inc. Ltd. is a technology-intensive corporation playing a leading role in producing fermented functional protein. Drawing on reliable research results of MIT (Massachusetts Institute of Technology), Zhejiang University, and China Academy of Agricultural Sciences, and Institute of Microbiology of China Academy, Cofine has focused on microbial fermentation and bioengineering. The company’s mission is to reduce the cost of feed, advance animal husbandry, and improve the quality of related produces. Fermentation engineering is an emerging core business of Myande. In recent years, “Myande” has developed into a widely recognized professional brand in the solid fermentation industry in China. Myande fermentation engineering has the following features: Integrated Solutions With strong integrative engineering capabilities, Myande provides its clients with complete package engineering services that cover site planning, civil design, process design, equipment R&D and supply, installation, commissioning, staff training, and after-sale service. With this comprehensive package, Myande is in a good position to ensure efficient and effective implementation of the whole project. First-class Mechanical Manufacture Myande always insists on the concept of “excellent manufacture”. Equipped with heavy-duty CNC lathes, laser cutting machine, pentahedron machining centers, welding robots intelligent warehouse, Myande ensures first-class quality and reliability of all machinery products. Three-Dimensional Design Myande is unique in the fermentation engineering industry in that it adopts advanced 3D technology in project design, which provides the client with remarkable benefits that include clear, accurate, and visualized presentation of plant overall structure, equipment layout, and piping system. Compared with traditional two-dimensional design, three- dimensional design provides more accurate positioning of equipment and piping, thus effectively avoiding interference between civil construction and equipment, shortening installation time, and improving installation efficiency. Customer Oriented Service Myande provides clients with mature and highly individualized solutions and process equipment based upon their specific needs and requirements. Myande fermentation equipment include rectangular trough fermentation bed, rectangular fermentation machine with controllable temperature and humidity, circular fermentation tower, and circular fermentation machine. Custom-made drying equipment include tube dryer, live drying tower, and circulation dryer. Automatic Control System Myande’s fermentation engineering services include design and supply of sophisticated automatic control system that enables precise adjustment of process parameters on the computer screen. Myande control system enables its clients to reduce labor cost and improve productivity.

Annually 20,000 Tons Feed Ingredient Fermentation Project

Recently, Myande Group and Taian Shengliyuan Bioengineering Co, Ltd, a branch of Taishan Liquor Group, reached an agreement by which Myande will undertake for Shengliyuan a 20,000 T/A meal fermentation engineering project. During business talks leading to the finalization of the project agreement, Myande with its comprehensive technological advantages won the approval and recognition of Taishan Group. Myande sales director Mr. Zhou Bin and Shengliyuan General Manager Mr. Xu Qimin signed the agreement. This cooperative project represents a major milestone of Myande’s efforts in promoting the trend of automation in China’s fermentation industry. According to the agreement, Myande will provide comprehensive engineering services, which will include process design, civil works design, design and supply of automation control system, equipment manufacture, installation, and commissioning. The major component of the project consists in a custom-designed 10,000 T/A aerobic yeast generating line and a 10,000 T/A anaerobic fermentation line. The project will adopt industry-leading process technology and reliable mechanical equipment to ensure reliability and stability of final product parameters. The fermentation section, which stands as the core part of the whole project, will adopt Myande’s patented circular fermentation tower, technical advantages of which includes compact structure leading to reduced space requirement and construction cost. The complete processing line, with compact and efficient layout planning, enables full automatic control of fermentation process and real-time monitoring of process parameters. All these features provide necessary prerequisite for ensuring high quality of the final products. As a “new & high technology enterprise” owned by Taishan Liquor Group, Taian Shengliyuan Bioengineering Co.Ltd specializes in the development, production and promotion of biological fermentation products. Following by its clearly-defined operational concept featuring "specialization” and “differentiation", Taian Shengliyuan has taken full advantage of its technological advantages in fermentation industry and has formed close cooperation ties with numerous well-known universities and research institutes at home and abroad to develop bio-protein feed and feed additives. With years of efforts, Taian Shengliyuan has grown into one of the leading suppliers of bio-protein feeds in China. Myande always treats every customer with a grateful heart. Adhering to the corporate culture of "passion and enthusiasm, precision, honesty", Myande will provide customers with secure, reliable and energy-saving equipment and engineering services for the objective of creating value for customers and the society.

Soybean Meal Fermentation & Drying Technology and Equipment

With the increasing popularity of feedstuff fermentation technology in China, the feed industry and breeding industry have put forward new requirements on the output and quality of fermented raw materials. The reliability of the fermentation raw materials production technology and equipment plays a decisive role in the quality. The moisture content of feedstuff after solid-state fermentation is normally about 40%, and it’s easy to deteriorate if improperly preserved. In addition, in the industrial production of feedstuff, it’s difficult to add wet materials to the feed production stage automatically. Therefore, most manufacturers of fermentation feedstuff need to adopt drying equipment to reduce the moisture content of feedstuff to be less than 13% for storage and transportation while ensuring its stability and quality. 1. Soybean Meal Fermentation Process The process of soybean meal solid fermentation can be briefly described as follows. Feed the strain to the raw materials and then add water for mixing until the moisture content of the fermentation materials is about 40%. Then, feed the material into fermentation equipment for solid-state fermentation, which generally lasts 2 to 4 days. After fermentation, drying the materials until the final product moisture content is not higher than 10%, then grind and pass through a 20~40 mesh sieve, and finally packaged. Traditional solid-state fermentation equipment tends to require a large amount of labor. Since the low level of automation, it is unsuitable for continuous production. Current intelligent solid-state fermentation equipment can automatically feed and discharge. The discharge is uniform and stable, and the back end can be connected with the drying system seamlessly, bringing products with excellent and stable quality and good fermentation effects. 2. Current Situation of Solid-state Fermentation Equipment At present, solid fermentation equipment in the industry mainly includes ground stacking fermentation, ton bag fermentation, above-ground tank fermentation, box fermentation, plastic bag fermentation and underground pool fermentation. Most such equipment has the following problems: low automation, requiring a large amount of labor; poor sanitary conditions, cross-contamination; being difficult to guarantee fermentation conditions; no large-scale and continuous production, if not controlled correctly, it’s likely to be counterproductive in the fermentation process (infected with bacteria and go moldy, produce toxins, etc.). However, the intelligent fermentation equipment has the following characteristics: continuous and scale production; automatic and intelligent operation; the fermentation environment is controllable to ensure the fermentation conditions; good sanitary conditions without cross-contamination and well-cleaned equipment; energy-efficient running which will reduce fermentation costs; fermentation and drying equipment is environmentally friendly. 3. Intelligent Fermentation Equipment 3.1 Automated rectangular fermentation bed (facultative aerobic) The materials are fed into the distributing machine by air, and then inoculated in the inoculation mixer, and finally be distributed; the fermentation bed has the auxiliary heating function, which is generally used for facultative or anaerobic fermentation; the bed thickness is usually 700 ~1,000 mm and it can be appropriately adjusted according to the actual production conditions; automatic feeding and material tumbling is realizable in the production process; after fermentation, the discharging is automatic, continuous, quantitative, uniform and stable discharging, and the back end can be seamlessly connected with the drying system. 3.2 Round fermentation tower It’s generally adopted for facultative or anaerobic fermentation, and is for high bed fermentation; the maximum bed thickness is 2,000 mm and it can be appropriately adjusted according to the actual production conditions; automatic feeding and discharging is realizable in the production process, and the discharging is continuous, quantitative, uniform and stable discharging, and the back end can be seamlessly connected with the drying system. Good anaerobic fermentation environment and excellent fermentation effects generate stable products. The capacity is 50~100T/batch. 3.3 Rectangular aerobic fermentation bed The fermentation machine can automatically adjust the temperature, humidity and ventilation quantity to control the fermentation process. The inoculated materials are fed into the fermentation machine, the bed thickness is usually 300~450 mm and it can be appropriately adjusted according to the actual production conditions; the machine is specially designed for shallow bed fermentation; automatic feeding and material tumbling is realizable in the production process; after fermentation, the discharging is automatic. 3.4 Round fermentation machine (aerobiotic) The fermentation machine can automatically adjust the temperature, humidity and ventilation quantity to control the fermentation process. The inoculated materials are fed into the fermentation machine, the bed thickness is usually 300 ~500 mm and it can be appropriately adjusted according to the actual production conditions; the machine is specially designed for shallow bed fermentation; automatic feeding and material tumbling is realizable in the production process; after fermentation, the discharging is automatic. 4. Drying Equipment 4.1 Shell and tube dryer Steam is in the tube pass and materials contact with the shell pass, and the materials are scattered by the shovelling plate, transported and dried in the dryer. The dryer has the following advantages: single equipment has large capacity, high efficiency and energy saving, low steam and electricity consumption for per ton of materials, continuous production. 4.2 Live drying tower The bed thickness is adjustable and the materials inside are in fluidized state and fully contact with hot air, which will generate a flash evaporation effect. The materials can be dried in the low temperature and continuous production and energy-saving are realizable. 4.3 Combined drying Combining the tube bundle dryer with the live drying tower: most water is removed from the materials in the tube bundle dryer, and then the materials are fed into the live drying tower for secondary drying, which fully takes advantage of the two machines, resulting in energy-saving and low-temperature drying. 4.4 Circulation drying at low temperature Large air volume, quick flash evaporation, and the low-temperature drying will ensure the material activity to the most extent, and it can realize the drying of viscous materials and meet the need for large capacity of single equipment.

Myande Awards 2022 “Spring Sunshine” Scholarship

In order to motivate employees' children to study hard and to enhance employees’ sense of belonging and happiness, on August 19, Myande held 2022 Myande Spring Sunshine Education Scholarship ceremony. Mr. Wangmu, vice chairman and Mr. Mao Weijiang, director in charge of manufacturing, participated in this ceremony and on behalf of the company presented scholarship stipends to children of Myande employees who are enrolled by four-year universities this year. In his speech, Mr. Wang highlighted that Spring Sunshine Scholarship is one of several company welfare benefits. It represents the company’s vision of moving forward with its employees and creating a better future together, and it reflects the company's care for the education of its employees' children and its high sense of social responsibility.

Contact Us

Contact us to see how we can help you grow your business.

Find the solution to an optimized future.