Steps of Biodiesel Manufacturing Process from Palm Oil

Oct 06, 2025

If you are considering starting a biodiesel project from palm oil, you’re probably wondering what the exact process looks like in real-world industrial plants. I’ve been involved in designing and commissioning biodiesel production lines for over two decades, and I’ve seen both the pitfalls and the success stories. The truth is—while the process is straightforward in theory, every step matters in practice.

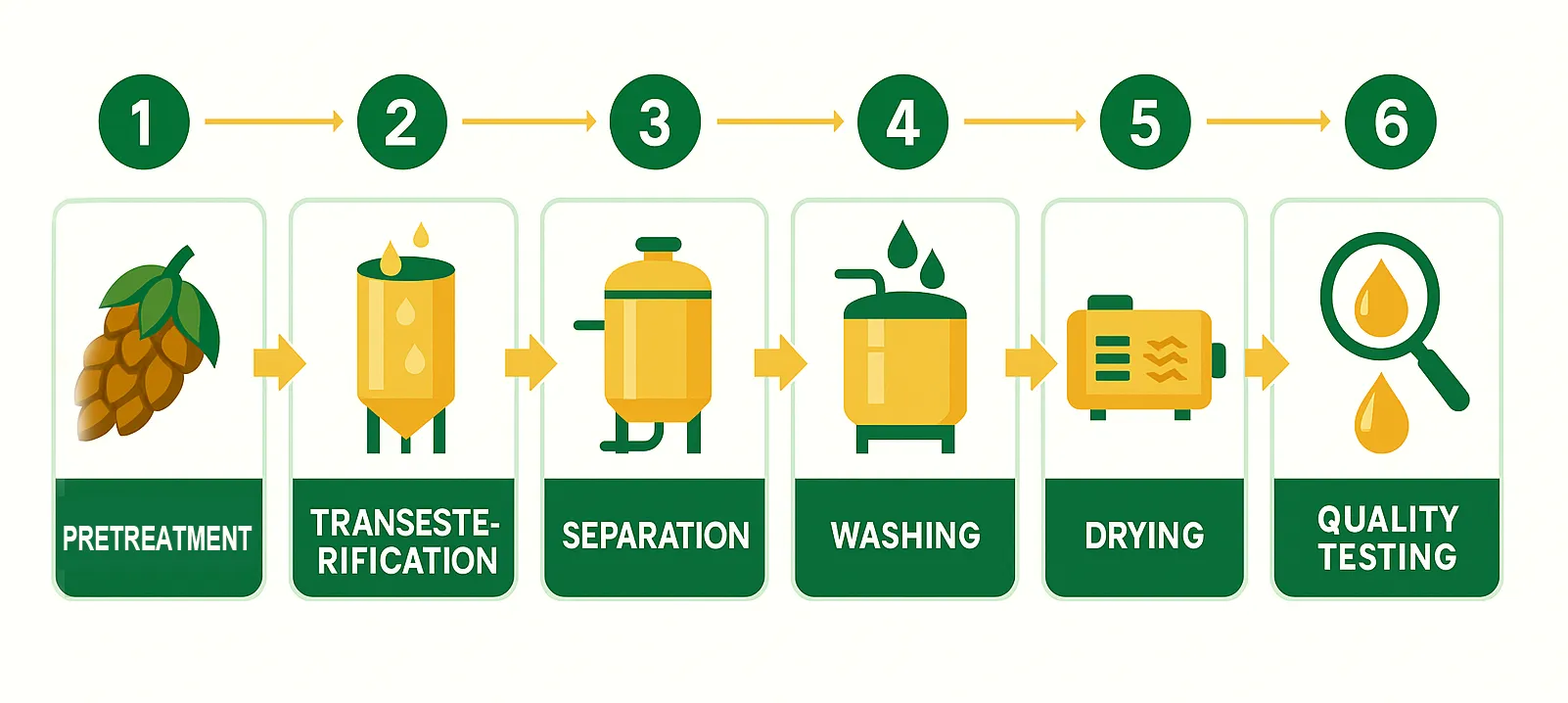

The biodiesel manufacturing process from palm oil typically involves pre-treatment of crude oil, transesterification with methanol and a catalyst, phase separation, washing, drying, and quality testing—each step carefully controlled to ensure fuel meets international standards.

In this article, I’ll walk you through each stage, share why certain steps can make or break your yield, and highlight insights that can save you time, reduce costs, and avoid common production issues. Whether you’re a new investor, an experienced plant manager, or a technical buyer, this guide will help you understand exactly how palm oil turns into clean, renewable biodiesel.

Steps of Biodiesel Manufacturing Process from Palm Oil

1. Preparation and Pre-treatment of Palm Oil

When we start with palm oil—whether crude palm oil (CPO) or refined, bleached, deodorized palm oil (RBDPO)—the first job is to prepare it for reaction. If the oil has a high free fatty acid (FFA) content, we can’t skip the acid esterification stage. This step converts FFAs into esters and reduces the risk of soap formation during transesterification.

In biodiesel production from high-FFA palm oil, acid esterification using methanol and an acid catalyst (such as sulfuric acid) is critical to reduce FFAs below 1% before base-catalyzed transesterification.

Skipping proper pre-treatment might seem like a time-saver, but in my experience, it always leads to lower yields, difficult separation, and higher downstream costs. Well-designed pre-treatment also removes impurities like water, gums, and solids that can poison catalysts.

|

Pre-treatment Step |

Purpose |

Typical Equipment |

|

Heating |

Reduce viscosity and prepare for reaction |

Heat exchangers, steam jackets |

|

Degumming / Neutralization |

Remove phospholipids and gums |

Degumming tanks, separators |

|

Acid esterification (if needed) |

Reduce FFAs for smoother transesterification |

Stirred reactors with acid dosing |

2. Transesterification Reaction

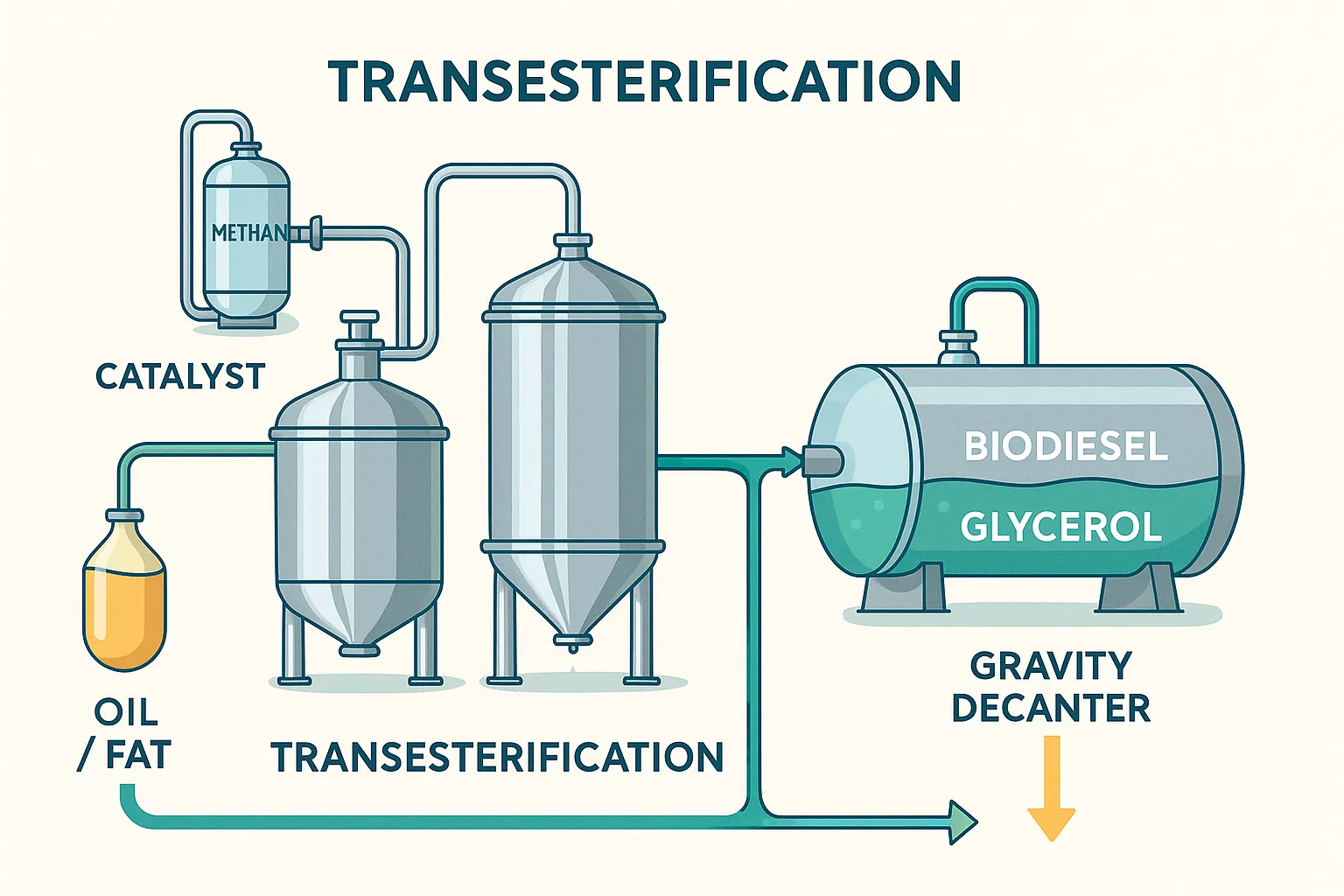

This is where the transformation happens. In the base-catalyzed transesterification process, palm oil triglycerides react with methanol in the presence of a catalyst like sodium hydroxide (NaOH) or potassium hydroxide (KOH). The goal: convert triglycerides into methyl esters (our biodiesel) and glycerol as a valuable byproduct.

During transesterification, palm oil reacts with methanol in the presence of a base catalyst to form biodiesel (methyl esters) and glycerol. Reaction conditions—temperature, methanol-to-oil ratio, and catalyst concentration—directly influence yield and quality.

In practice, we maintain the temperature around 55–65°C, ensure a methanol-to-oil molar ratio of about 6:1, and keep water content minimal. These parameters are non-negotiable if you want consistent, spec-compliant biodiesel.

3. Separation of Biodiesel and Glycerol

After the reaction, the mixture needs time to settle. Gravity naturally separates the lighter biodiesel layer from the denser glycerol layer.

Biodiesel and glycerol separate into two layers by gravity—biodiesel on top and glycerol at the bottom—allowing easy decanting or separation.

At scale, we use decanters or centrifuges to speed up the process. Glycerol is not waste—it’s a marketable byproduct for pharmaceutical, cosmetic, and chemical applications once refined.

4. Washing and Purification

Freshly separated biodiesel still contains residual methanol, catalysts, soap, and trace impurities. Washing with water—sometimes with mild acid—removes these contaminants.

Biodiesel is washed with warm water or mild acid to remove residual catalyst, soap, and impurities until the wash water is neutral.

In my plants, we monitor pH closely and avoid over-washing to prevent emulsions. Some modern setups use dry washing with ion exchange resins to eliminate water usage.

5. Drying and Final Quality Testing

The washed biodiesel must be dried to remove moisture, which can cause corrosion in storage tanks and fuel systems.

Biodiesel is dried using heat or vacuum systems to achieve moisture content below 500 ppm, then tested for density, cetane number, viscosity, and other fuel standard parameters.

Before releasing the product, we run quality tests according to ASTM D6751 or EN 14214 standards. Meeting these benchmarks is not optional—it’s your ticket to the commercial biodiesel market.

Summary Table of Palm Oil Biodiesel Process

|

Step |

Key Actions |

Typical Outcome |

|

Pre-treatment |

Heat, degum, reduce FFAs |

Stable feedstock for reaction |

|

Transesterification |

React oil with methanol & base catalyst |

Conversion to biodiesel + glycerol |

|

Separation |

Decant or centrifuge layers |

Clean phase split |

|

Washing |

Water/mild acid wash |

Removal of residual chemicals |

|

Drying |

Heat or vacuum dry |

Moisture-free biodiesel |

|

Quality Testing |

ASTM/EN standard checks |

Market-ready biodiesel |

What is the Physical Refining Process of Palm Oil?

When we physically refine palm oil before biodiesel production, we follow four main steps: degumming, bleaching, deacidification, and deodorization.

Physical refining of palm oil involves degumming to remove gums, bleaching to adsorb pigments, steam-based deacidification to strip FFAs, and deodorization to remove odors and volatiles.

This method avoids chemical neutralization, reduces wastewater, and yields high-quality RBD palm oil. It’s the preferred route when producing both edible oil and biodiesel feedstock.

What is the Most Common Source of Biodiesel Production?

Globally, different regions favor different feedstocks, but one stands out.

Soybean oil is the most common feedstock for biodiesel production, accounting for about 77% of US biodiesel feedstock usage, followed by animal fats, canola oil, and used cooking oil.

Palm oil plays a major role in Southeast Asia, especially in Indonesia and Malaysia, while soybean oil dominates in the Americas. The choice often comes down to regional availability and price stability.

Conclusion

Producing biodiesel from palm oil is not just about following a recipe—it’s about controlling every variable to achieve consistent quality. From the first heating in pre-treatment to the final quality test before shipping, each step directly affects yield, cost, and market acceptance.

If you’re planning a biodiesel project, investing in robust process design and reliable equipment will pay off in smoother operations and higher profitability. After all, in my 20+ years in this industry, I’ve learned one thing: quality biodiesel starts with quality processing.