Development and Utilization of Corn Processing By-Products

Sep 08, 2025

Introduction

When we talk about the corn processing industry, most people immediately think of starch, glucose, or ethanol. But from my 20+ years in turnkey corn processing solutions, I can tell you that the real untapped value often lies in the by-products. These streams, once considered waste, can actually drive profitability and sustainability if handled properly.

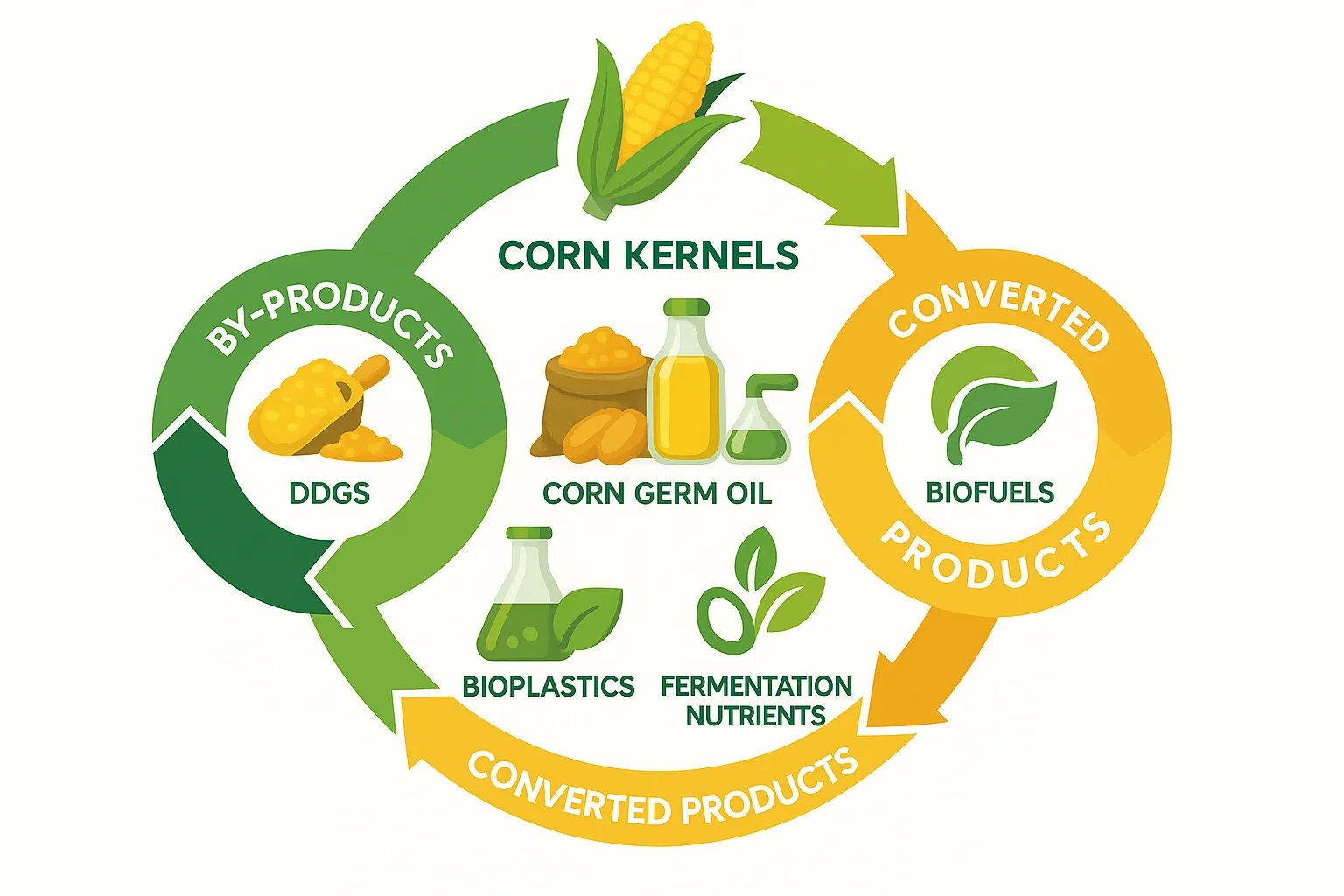

The development and utilization of corn processing by-products transform what was once industrial waste into high-value resources for animal feed, biopolymers, biofuels, and functional ingredients—reducing environmental impact while improving economic returns.

In this article, I’ll walk you through the major types of corn by-products, their industrial applications, and how technology is reshaping their role. If you’re running or planning a corn processing plant, these insights could be the key to higher margins and a stronger environmental profile.

1. Key Corn By-Products and Their Utilization

In corn processing, whether through wet milling or dry milling, multiple by-product streams emerge alongside the main product. These include protein-rich meals, fibrous husks, nutrient-dense liquids, and oil-rich germ.

Corn gluten meal and corn gluten feed are high-protein by-products from wet milling, corn husks and cobs are valuable lignocellulosic materials for bio-based products, corn germ yields edible oil, and distillers’ grains from ethanol plants provide essential livestock feed.

Here’s a breakdown of the most common by-products and their uses:

|

By-Product |

Source Process |

Primary Use |

Key Value |

|

Corn Gluten Meal (40–60% protein) |

Wet milling |

Animal feed for poultry, cattle, aquaculture |

High-protein, high-digestibility feed |

|

Corn Gluten Feed |

Wet milling |

Dairy and beef cattle feed |

Balanced protein and fiber |

|

Corn Husks, Stalks, Leaves, Cobs |

Field residue |

Biodegradable plastics, composites, biomass fuel |

Lignocellulosic raw material |

|

Corn Steep Liquor (CSL) |

Wet milling |

Fermentation nutrient, animal feed supplement |

Rich in soluble proteins, amino acids |

|

Corn Germ |

Wet milling |

Corn oil extraction |

High oil content |

|

Ethanol production |

Livestock feed |

Protein and energy-rich co-product |

By strategically developing applications for these streams, plants can achieve a circular economy model, where every part of the corn plant is utilized.

2. Industrial Trends in By-Product Utilization

Global demand for sustainable raw materials is pushing corn processors to innovate. In my experience, several trends stand out:

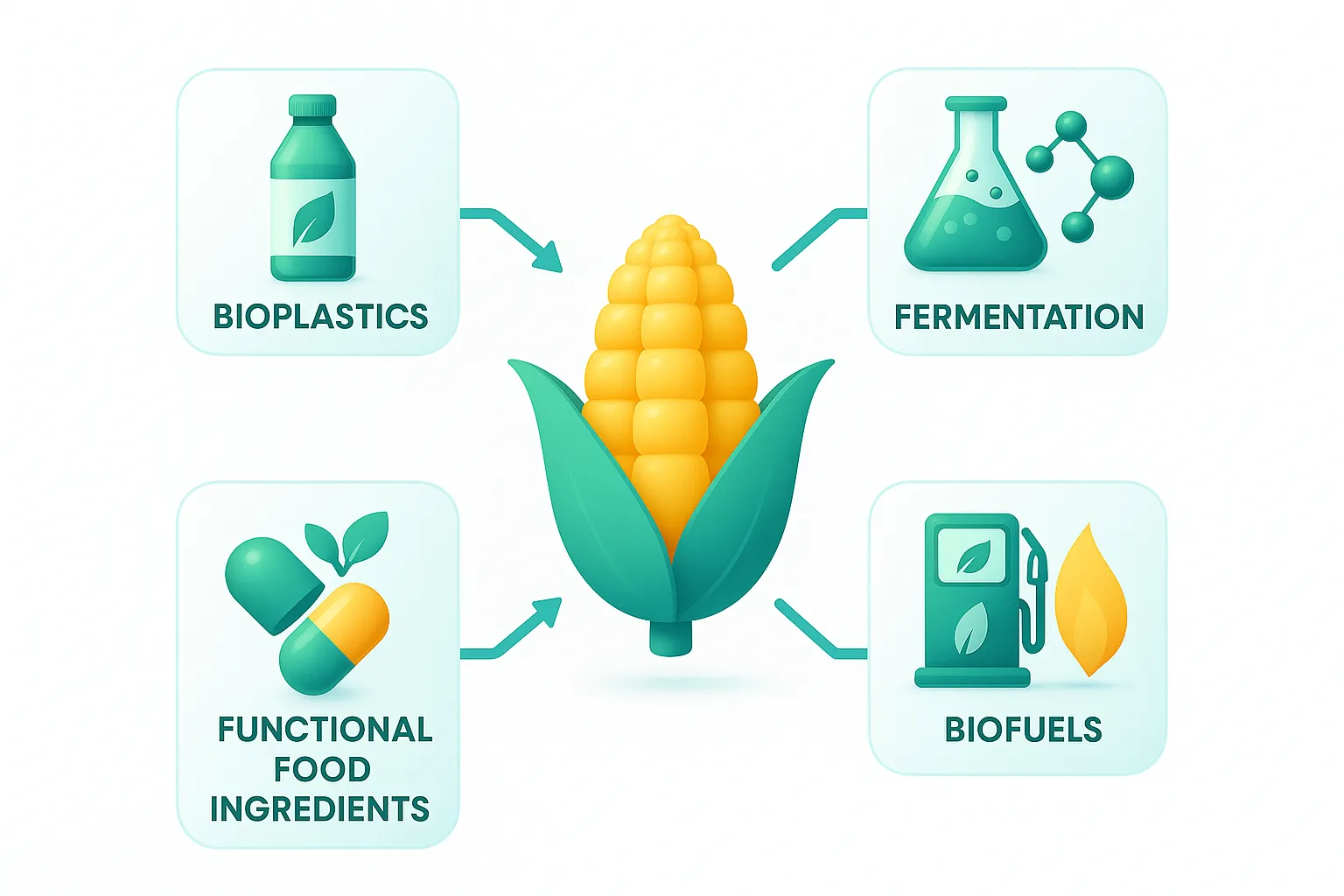

Innovations in biopolymer production, functional food ingredients, and bioenergy are elevating the value of corn by-products, making them competitive with traditional petrochemical-based materials.

For example, corn husks and cobs are now used in producing biodegradable plastics and hydrogels. Corn steep liquor finds its way into amino acid and antibiotic fermentation processes. DDGS not only serves livestock but is increasingly used in aquaculture feed formulations.

3. Environmental and Economic Benefits

Beyond direct profits, by-product utilization brings tangible sustainability gains.

Lower waste means fewer disposal costs and reduced environmental footprint.

In many regions, regulators now encourage or even mandate resource recovery.

The secondary use of corn by-products reduces waste, supports carbon reduction goals, and enhances economic resilience by diversifying revenue streams.

From an operational standpoint, selling refined by-products can provide steady income even during market downturns for primary products like starch or ethanol.

How is Corn Steep Liquor Produced?

When we process corn via wet milling, steeping is one of the first steps. It’s here that corn steep liquor (CSL) is created.

Corn steep liquor is produced by soaking cleaned corn kernels in warm water with a small amount of sulfur dioxide, extracting soluble nutrients into the water, which is then concentrated by evaporation.

Here’s a simplified production flow:

1. Steeping: Cleaned, shelled corn is soaked at 45–52°C (113–125°F) in water containing 0.1–0.2% sulfur dioxide for 30–48 hours.

2. Separation: Softened kernels are coarsely ground; insoluble fractions like germ and bran are removed.

3. Concentration: Steep water is concentrated in multiple-effect evaporators to reach 45–55% solids.

4. Storage or Drying: CSL is stored as a liquid or spray-dried for powder applications.

CSL’s nutrient profile—soluble proteins, amino acids, vitamins—makes it a valuable fermentation feedstock in industries like antibiotics, enzymes, and organic acids.

How to Produce Ethanol from Corn

Corn ethanol production is well established, but efficiency depends on how well each step is controlled.

Ethanol from corn is produced through milling, enzymatic starch hydrolysis, fermentation with yeast, distillation, and dehydration to produce fuel-grade ethanol.

Here’s the process in brief:

1. Milling: Corn is ground into meal.

2. Liquefaction: Meal is mixed with water and alpha-amylase, breaking starch into shorter chains.

3. Saccharification: Gluco-amylase converts starch fragments into glucose.

4. Fermentation: Yeast consumes glucose, producing ethanol and CO₂.

5. Distillation: Ethanol is separated from solids and water, reaching ~95% purity.

6. Dehydration: Molecular sieves remove remaining water to yield anhydrous ethanol.

7. Co-Products: Solids become DDGS for livestock feed.

The co-product value from DDGS often accounts for a significant share of ethanol plant revenue.

Conclusion

From my perspective, the development and utilization of corn processing by-products is not just an environmental duty—it’s a business growth strategy. Whether it’s converting husks into biodegradable plastics, using CSL in fermentation, or selling DDGS to feed markets, every stream offers an opportunity.

For processors, the challenge isn’t whether these by-products have value—it’s whether you have the right technology and market connections to realize that value. With integrated engineering solutions, every part of the corn plant can work for your bottom line.