A Guide to Setting Up a Palm Kernel Oil Refinery Plant

Jul 22, 2025

Starting your own palm kernel oil (PKO) refinery plant is an ambitious yet highly rewarding journey. I’ve had the privilege of working with clients in more than 80 countries, and I’ve seen firsthand how a well-planned refinery transforms a business. Whether you're a farmer looking to scale up or an investor seeking high-yield opportunities, this guide will help you navigate the path.

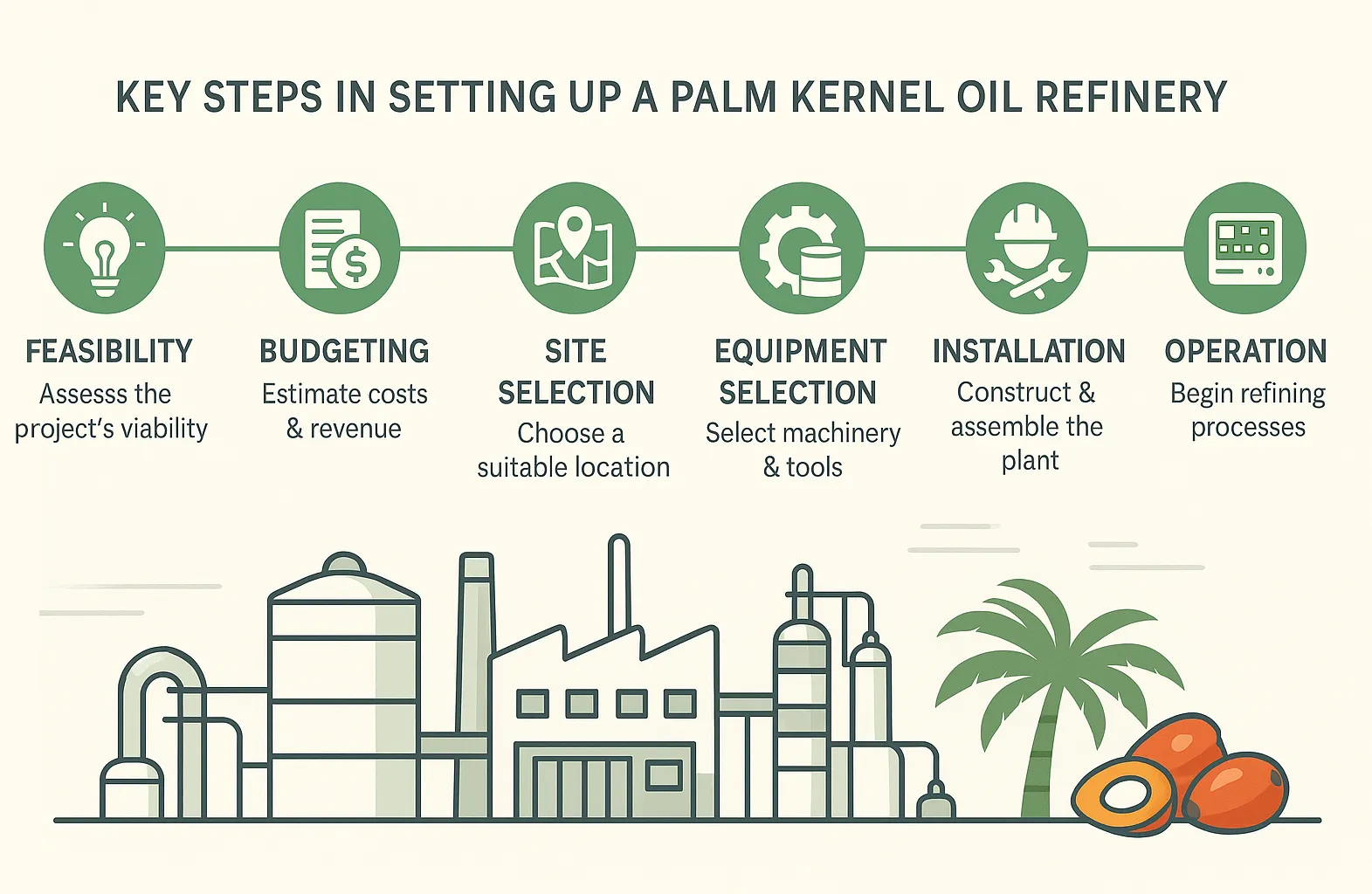

Setting up a palm kernel oil refinery plant involves market research, budgeting, choosing the right equipment, site selection, and engineering design. Each decision can make or break your success.

In this article, I’ll walk you through every key step, share practical insights, and offer tips learned through years of on-the-ground experience. Let’s begin where it all starts: understanding the roadmap to your refinery.

What Are the Key Steps to Set Up a Palm Kernel Oil Refinery Plant?

Start with Feasibility and Planning

Before investing in equipment or land, take a close look at your target market. Who will buy your refined palm kernel oil? What’s the demand for it locally or internationally? A solid feasibility study will help answer these.

You should assess demand, production costs, ROI expectations, and potential market risks before making any big decisions.

Feasibility doesn’t stop at the spreadsheet. Talk to local authorities about compliance. Visit existing plants. Benchmark prices for raw kernels and refined oil. This groundwork prevents costly mistakes.

Key Steps at a Glance

|

Stage |

Purpose |

What You Need to Do |

|

Feasibility Study |

Assess market, cost, risk |

Market research, cost modeling, ROI projection |

|

Budget & Capacity Plan |

Define output and investment scale |

Choose batch/continuous refining, cost breakdown |

|

Site Selection |

Optimize logistics and compliance |

Proximity to raw material, infrastructure, utilities |

|

Plant Design |

Ensure process efficiency |

Layout, process flow, future scalability |

|

Equipment Selection |

Guarantee performance and safety |

Choose trusted brands with proven reliability |

|

Installation |

Smooth startup and staff readiness |

On-site setup, trial run, training |

|

Operations & QC |

Maintain quality and uptime |

Skilled staff, SOPs, ongoing equipment maintenance |

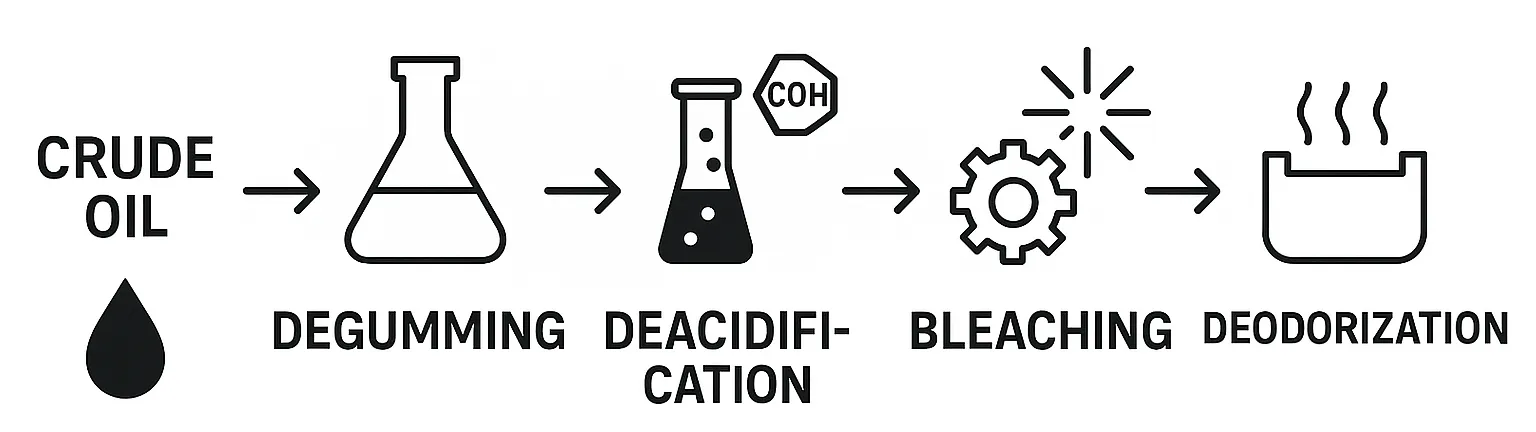

What Is the Process of Refining Palm Kernel Oil?

Once you’ve extracted crude palm kernel oil, the goal is to remove all impurities—like free fatty acids, gums, and pigments—so the final product is food-grade. The refining process typically includes four key steps.

The palm kernel oil refining process includes degumming, deacidification, bleaching, and deodorization, ensuring removal of all harmful or unstable components.

Each step plays a vital role in improving the oil’s shelf life, appearance, taste, and market value. Here's how the process works:

Palm Kernel Oil Refining Process

|

Step |

Purpose |

Common Method |

|

Remove phospholipids and gums |

Phosphoric acid + hot water |

|

|

Remove free fatty acids |

Alkali neutralization or steam distillation |

|

|

Remove pigments and impurities |

Activated clay (bleaching earth) + filtration |

|

|

Eliminate odors and volatiles |

Steam distillation under vacuum at ~240–260°C |

Degumming and deacidification often overlap. For small-scale setups, alkali neutralization is cheaper. But for large refineries, physical refining via steam is more efficient and chemical-free.

Bleaching improves appearance and storage stability. Finally, deodorization ensures the oil is odorless, making it suitable for food and cosmetics.

How Lucrative Is the Palm Kernel Oil Business?

You’re probably wondering—is it worth the investment?

The palm kernel oil market is expected to grow from USD 5.13 billion in 2025 to nearly USD 7.73 billion by 2033, driven by demand in food, cosmetics, and biofuel sectors.

This steady 5.2% CAGR shows the market is robust and growing. Emerging markets like Nigeria, Indonesia, and India are driving both supply and demand.

Why It's a Profitable Business

Let me break it down for you:

- 1. Multiple Applications

Palm kernel oil is used in food processing, margarine, cosmetics (soap, cream), and industrial lubricants. - 2. Rising Demand for Sustainable Oils

More consumers want ethically sourced, plant-based ingredients. - 3. High Yield per Hectare

Compared to other oilseeds, palm yields are far higher—especially when refined efficiently. - 4. Government Support

Countries like Nigeria and Malaysia offer incentives for palm oil processors.

When you refine PKO locally, you capture more value than just exporting crude oil. You can also branch into value-added products like olein and stearin via fractionation.

What Equipment Do You Need?

Your equipment depends on your capacity and process type (batch or continuous). Here's what a typical setup includes:

- ●Palm Kernel Nut Cracker & Shell Separator

- ●Palm Kernel Cooker

- ●Oil Expeller (Screw Press)

- ●Crude Oil Clarifier

- ●Refining Units: Degumming, Deacidification, Bleaching, Deodorization

- ●Storage Tanks & Packaging Lines

Want it all in one place? That’s where we come in. At Myande Group, we design and manufacture complete turnkey solutions, from 3D layout to after-sales support.

We also help you automate processes for higher yield and lower cost.

What About Installation and Operation?

Installation isn’t just plugging in machines—it’s about process calibration, training your team, and ensuring every valve and sensor works as expected.

It’s crucial to follow the manufacturer’s guidelines for installation, conduct trial runs, and train your staff for efficient operations.

You’ll also want a reliable partner who offers technical guidance, commissioning services, and after-sales support—not just equipment delivery. Without that, even the best machines won’t perform.

Final Thoughts

Setting up a palm kernel oil refinery plant isn’t just about machines—it’s about strategy, process, and people. Done right, it brings incredible returns—not just financially, but in terms of job creation, sustainable development, and industrial value addition.

If you're ready to begin your journey into palm kernel oil refining, we at Myande Group are here to help with tailored turnkey solutions—from idea to installation.

For a detailed consultation or to request a custom quote for your project, feel free to contact our team.

Let’s build something powerful—together.