How Do Myande’s Starch Equipment and Services Drive New Industry Trends?

Jan 14, 2026

As a fundamental and critical step in industries such as food, pharmaceuticals, and chemicals, starch processing directly affects the quality and cost of end products. In this field, the performance of high-end starch processing equipment and the level of technological innovation have become key factors for companies seeking to enhance their competitive edge.

As a global leader in starch machinery manufacturing, Myande Group has established an industry benchmark in starch processing. Leveraging its deep technical expertise, intelligent manufacturing capabilities, and comprehensive end-to-end service system, Myande sets the standard for excellence in the field.

01 | Core Technologies Driving Closed-Loop and Sustainable Starch Processing

Myande’s proprietary “Steeping, Milling, Separation” wet-process technology leverages a closed-loop workflow to significantly reduce water consumption and minimize wastewater discharge, while boosting starch dry matter recovery to industry-leading levels. For example, in corn starch production, this process not only lowers water usage and reduces pollution but also helps clients achieve the dual goals of energy savings and environmental compliance, combining efficiency with sustainability.

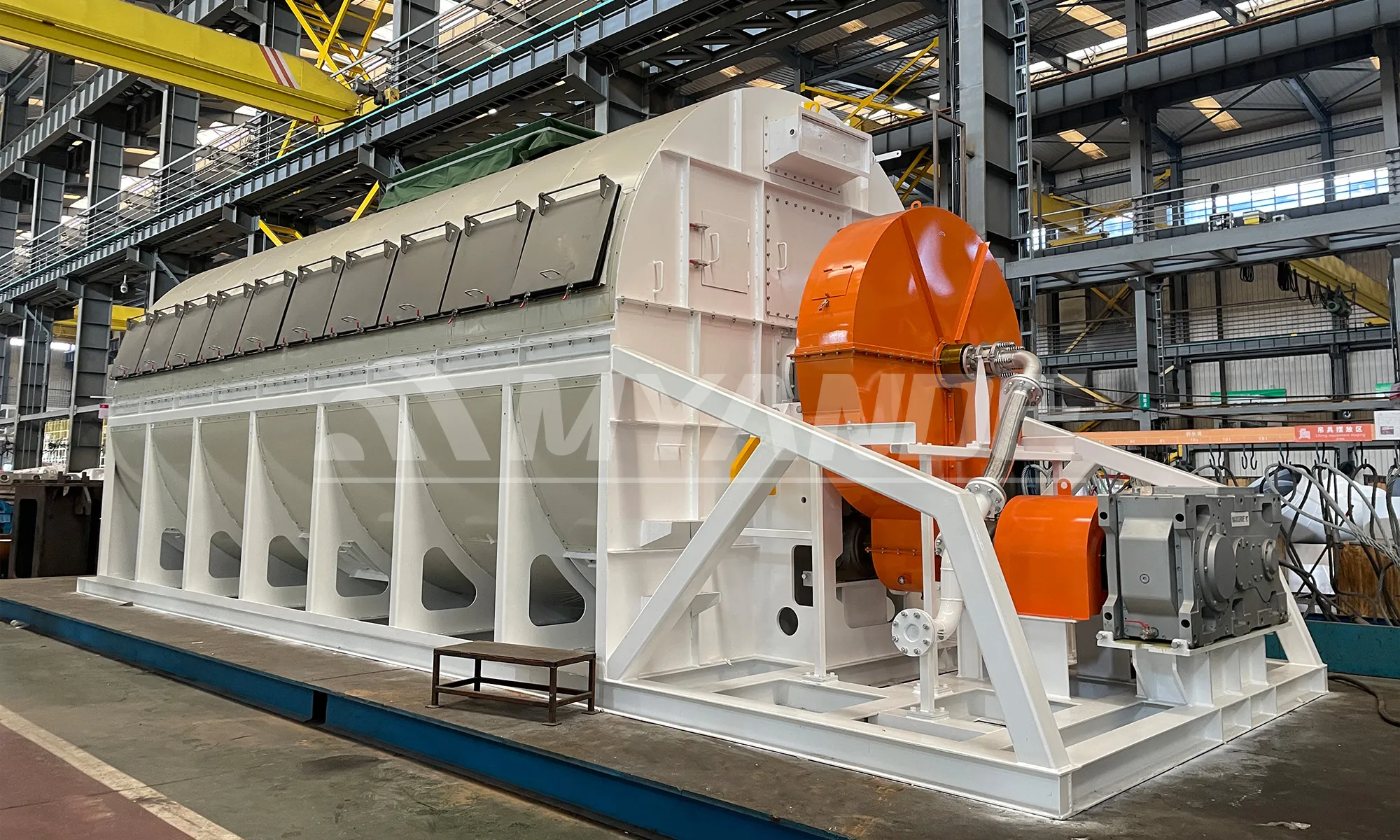

At the same time, Myande employs milling technology with a processing capacity of 18–25 tons per hour (MZM1200 model), adaptable to a variety of raw materials including corn, tubers, and legumes. The system ensures precise particle size control, improving starch yield while keeping residual starch content below 15%. Following milling, centrifugal separator efficiently separate and enhance purity, and tube bundle dryer stabilize the starch moisture content. The complete system occupies minimal floor space and combines energy efficiency with environmental benefits, helping clients reduce operational costs while maintaining high performance.

02 | Smart Manufacturing and Tailored Service Solutions

Considering the diverse needs of different industries and clients, Myande offers fully customized, one-stop solutions, providing end-to-end lifecycle services that cover process design, equipment manufacturing, installation, commissioning, and after-sales support.

Myande has also developed a 130,000 m² intelligent manufacturing base, equipped with advanced technologies such as laser cutting, robotic welding, and smart distribution systems to produce customized equipment with high precision and long service life. Its Industry 4.0 smart control system supports remote monitoring, fault diagnosis, and real-time optimization of production parameters, effectively shortening project timelines and enabling clients to start operations sooner and maximize efficiency.

Myande’s services go beyond process design, equipment manufacturing, and installation, extending to staff training and after-sales support. Clients only need to handle civil construction, significantly reducing project management complexity. The group also provides a 24/7 professional service team ready to address technical issues at any time, while maintaining detailed client records and offering customized maintenance plans. By aligning with industry trends, Myande helps clients upgrade automation systems or expand production capacity, creating a comprehensive service ecosystem that effectively safeguards operational efficiency and maximizes client benefits.

With technological innovation at its core, Myande Group leverages intelligent manufacturing, a global service network, and academy-level R&D resources to provide efficient, green, and fully customized solutions for starch processing enterprises. Its equipment and technologies not only enhance production efficiency and product quality but also drive the industry toward low-carbon, high-value-added development, positioning Myande as a key partner for clients competing on a global scale.