How “Champion Enterprise” Myande Became a Benchmark in Intelligent Liquor Brewery Industry

Nov 12, 2025

As China’s liquor industry accelerates toward digital transformation and diversified development, leveraging digital intelligence to cultivate new productivity and enhance liquor quality has become the essential path for high-quality growth in the sector.

With over two decades of dedication to intelligent equipment manufacturing, Myande has established a comprehensive ecosystem of smart technologies spanning from raw grain processing to distiller’s grain recycling. This empowers liquor producers to integrate intelligent manufacturing and green brewing throughout the entire process, from grain aroma to liquor aroma. Leading liquor brands are now actively embracing technological innovation as a key driver of modernization.

Recently, a team from JiuYeJia, a leading industry media outlet, visited Myande Group to speak with Zhou Bin, Director of Myande Starch and Brewing Division, and Xu Jinfei, Head of the Brewing Engineering Sales Center, to learn how Myande is enabling liquor producers to improve both efficiency and product quality.

From a Single Grain to a Drop of Liquor – Myande’s Evolutionary Solution

When a sorghum kernel awaits fermentation in a temperature-controlled grain silo, Myande has already mapped out a full-process plan to transform that grain into a drop of liquor.

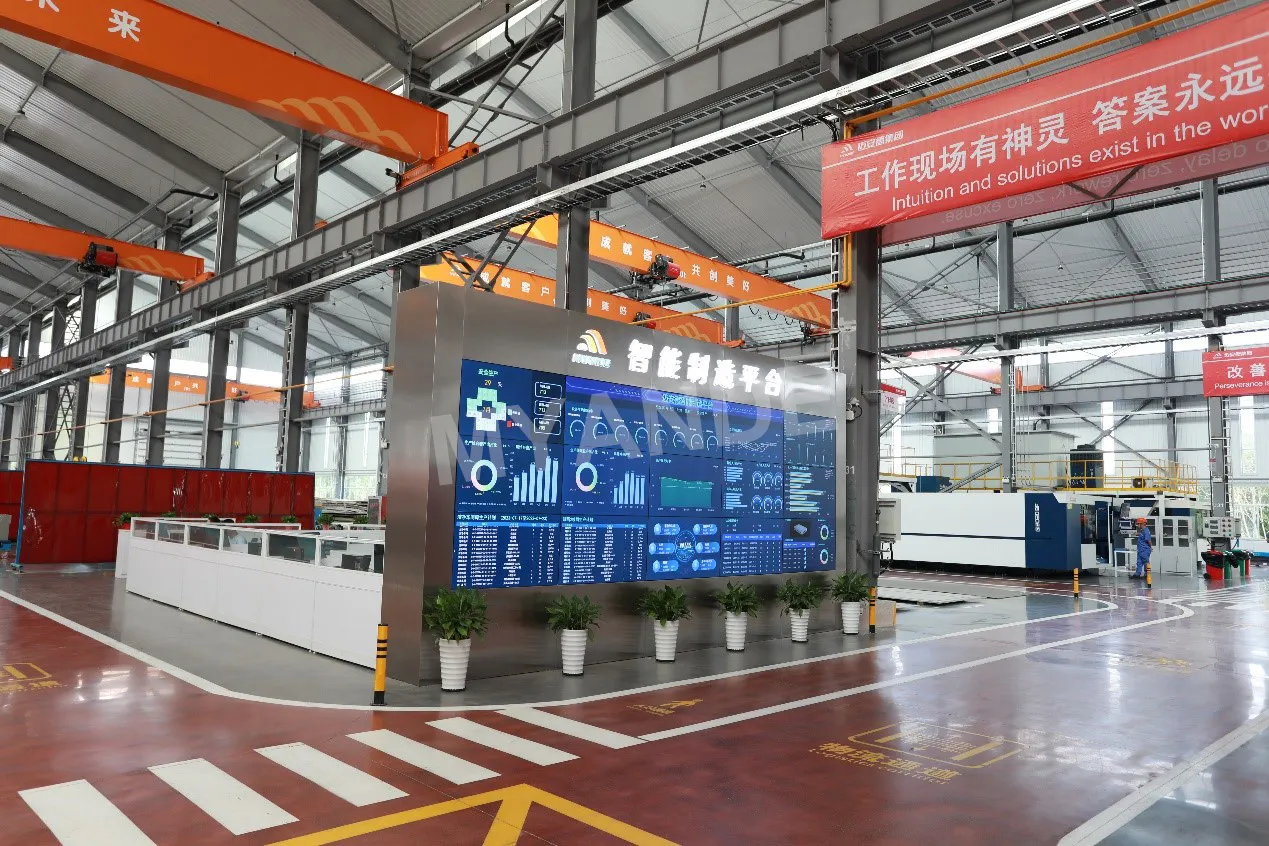

Founded in 2003, Myande specializes in oils and fats, starch and derivatives, fermentation, evaporation and crystallization, silo storage and conveying, and smart factory industries. The company provides one-stop turnkey project services covering project planning, engineering design, research and development, equipment manufacturing, automation, installation, and training support. Its technical capabilities and intelligent manufacturing platform now rank among the best in the world.

“We entered the intelligent liquor brewing field relatively late, only in 2021, but with a very high starting point. Many of our technologies are already at the global forefront. The smart brewing solutions we have delivered to leading Chinese liquor brands represent some of the most advanced systems in the industry,” said Xu Jinfei. “With more than 20 years of manufacturing experience in the grain and oil processing industry, we have accumulated deep technological know-how, enabling us to quickly emerge as a leader in smart brewing.”

Despite entering the liquor brewing sector only a few years ago, Myande has leveraged over two decades of deep technological expertise to quietly build a comprehensive ecosystem of intelligent equipment from raw grain handling to distiller's grain regeneration. This full-process integration not only revitalizes traditional Chinese brewing techniques but also enables ancient craftsmanship to thrive within modern intelligent systems.

According to the introduction, Myande’s intelligent brewing system encompasses a full suite of integrated modules, including a rapid transfer and storage system for raw and auxiliary liquor materials, a grain crushing and blending system, a precision dosing system, a yeast making and crushing system, an integrated rice husk steaming unit, a moistening and heap fermentation system, and a distiller’s grain recycling unit. Together, these systems orchestrate a seamless transformation from raw grain to premium liquor.

In the raw grain pretreatment stage, the cantilever reclaimer employs a patented anti-arching design to resolve challenges posed by high-moisture material retention. It works seamlessly with the integrated rice husk steaming unit, which efficiently removes harmful substances such as furfural through a continuous steam penetration process.

During the core fermentation phase, the disk-type yeast cultivator and heap fermentation system function as microbial ecosystem managers, precisely regulating the 300 to 1000 mm material layer using a distributed network of temperature and humidity sensors. This creates an optimal fermentation environment for jiupei, the fermented mash that precedes liquor filtration.

At the final stage of brewing, a tube bundle dryer and live dryer form a cascading energy utilization system that transforms fresh spent grain into high-protein animal feed, supporting green and low-carbon processing of distiller’s grain.

These innovations significantly enhance brewing efficiency, ensure product consistency, and enable circular use of resources, pushing the industry toward a greener, smarter, and more sustainable future.

50 Percent Energy Reduction – Innovation Is the Core Driving Force of Myande

According to Xu Jinfei, Myande has formed strategic partnerships with leading liquor producers in the industry. Myande provides comprehensive solutions from raw grain processing to yeast production and intelligent steaming systems, continuously helping enterprises upgrade their productivity through smart technologies.

Despite a challenging market environment and reduced investment from many liquor enterprises in recent years, Myande’s brewing segment has continued to grow at a steady annual rate of 10 to 20 percent. “Our competitive edge lies not only in product quality but also in our relentless equipment innovation, especially in improving the quality of raw and auxiliary brewing materials,” said Xu.

The application of the rice husk intelligent steaming system brings three core benefits to liquor enterprises. Firstly, quality enhancement: by enabling real-time monitoring of key parameters such as temperature and time, the system ensures the steaming process operates in an optimal and stable state, thereby guaranteeing consistent quality of auxiliary materials. Secondly, energy efficiency: through steam recycling and waste heat recovery technologies, the system significantly improves steam utilization while reducing exhaust emissions. Thirdly, investment savings: this integrated unit combines both the steaming and cooling functions into a compact footprint, effectively reducing investment costs in plant construction and land usage.

“In one project, the application of the Myande rice husk steaming system increased steaming efficiency by over 70 percent, boosted capacity by 65 percent, and reduced operational costs by more than 41 percent,” said Xu. Additionally, with Myande’s support, the production workshop has also achieved 8S management, greatly enhancing enterprise competitiveness.

According to Zhou Bin, Myande employs over 1,400 people, more than 65 percent of whom are R&D staff. The company has established a robust multi-generational innovation team and invests nearly 5 percent of its annual profit into new product and technology development. “Innovation is the core driver that gives Myande its strategic edge,” he explained. “At the intersection of digital and real economies, we are focused on technological advancement, industrialization of research outcomes, and strengthening our competitive edge in core technologies, continuously elevating productivity in the liquor industry.”

Relying on platforms such as the Academician Grain and Oil Deep Processing Innovation Center, Myande has secured over 500 valid intellectual property rights, including more than 100 invention patents. The company has led five major national projects under the Torch Program and developed full-process turnkey capabilities encompassing consulting, planning, process design, manufacturing, installation, commissioning, training, and after-sales service.

Notably, during the first round of supplier evaluation by the China Alcoholic Drinks Association, 47 experts conducted a rigorous two-year anonymous assessment. Myande was the only supplier awarded dual honors for Engineering Design and Equipment Manufacturing, which underscores its unmatched strength in the field of intelligent brewing.

From a single grain to a fine bottle of liquor, Myande is redefining equipment standards with full-chain intelligent systems. The company will continue integrating digital technology with brewing craftsmanship, breathing new life into centuries-old traditions through precision engineering.