How to Set Up an Edible Oil Refining Plant in Africa?

Nov 22, 2024

As I sit down to write this, I'm reminded of the countless conversations I've had with entrepreneurs and industry leaders who are eager to tap into the vast potential of the African market. The prospect of setting up an edible oil refining plant in Africa is both exciting and challenging. It's a venture that promises substantial rewards, but it also requires careful planning and execution. In this article, I’ll share insights from my experience, hoping to guide you through the essential steps of establishing a successful edible oil refining plant in Africa.

The Opportunity: Why Africa?

Africa’s economic landscape is changing rapidly, with increasing urbanization and rising disposable incomes driving demand for high-quality edible oils. But with opportunity comes the need for a clear plan. Without the right approach, even the most promising business can struggle to find its footing. So, how can you ensure that your edible oil refining plant not only survives but thrives in Africa? Let’s walk through the critical steps.

Key Steps to Set Up an Edible Oil Refining Plant in Africa

Setting up an edible oil refining plant in Africa involves several strategic decisions. Here’s a roadmap to help you navigate the process:

1. Raw Material Availability

The first step in setting up your plant is to secure a reliable supply of raw materials. Africa is rich in oilseeds, nuts, and fruits, which are essential for oil production. Depending on your target market, you might consider palm oil, groundnut oil, or shea butter. Ensuring a consistent supply of these raw materials is crucial. This may involve establishing relationships with local farmers or investing in plantations. Without a steady stream of raw materials, your plant will struggle to meet production targets and maintain quality.

2. Plant Location

Choosing the right location for your plant is a decision that will impact every aspect of your business. Ideally, your plant should be situated in a region with good infrastructure, including access to roads, utilities like water and electricity, and proximity to your raw material sources and target markets. Industrial areas or special economic zones can offer additional benefits, such as tax incentives and easier access to utilities. The right location not only reduces operational costs but also enhances the efficiency of your supply chain.

3. Plant Capacity

Determining the ideal capacity for your plant is a balancing act between your investment budget, raw material availability, and market demand. It’s often wise to start with a modular plant design, which allows you to begin with a smaller capacity and scale up as your business grows. Popular capacities range from 50 tons per day (TPD) to 500 TPD. A modular approach reduces initial capital expenditure and allows you to expand your operations in response to market dynamics.

4. Refining Process

The refining process is the heart of your operation, and it’s essential to choose the right method for your specific needs. You’ll need to decide between chemical refining and physical refining, each with its advantages depending on the type of oil you’re producing.

Chemical Refining: Suitable for oils with high phospholipid content, such as soybean and cottonseed oil. This process involves several steps, including degumming, neutralization, bleaching, and deodorization.

Physical Refining: Often used for oils with lower phospholipid content, such as palm oil and coconut oil. This method skips the neutralization step, removing free fatty acids during the deodorization phase.

Choosing the right refining process is critical to ensuring the quality and safety of your final product. Consulting with experts and possibly conducting pilot trials can help determine the most suitable process for your plant.

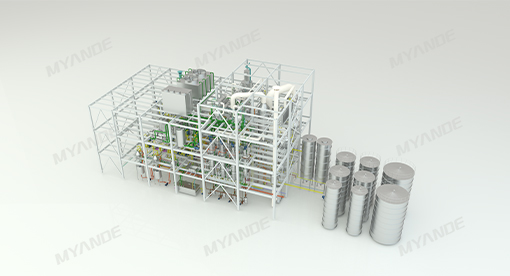

5. Machinery and Equipment

Investing in high-quality machinery and equipment is non-negotiable if you want to produce top-grade edible oils. You’ll need to procure essential equipment like expellers, filters, tanks, and heat exchangers. Working with reputable manufacturers who offer turnkey solutions, including installation and training, can save you time and reduce risks. Chinese manufacturers, known for their cost-effective and reliable machinery, are often a popular choice for projects in Africa. The right equipment will not only ensure operational efficiency but also help maintain consistent product quality.

6. Regulatory Approvals

Navigating the regulatory landscape is an essential step in setting up your plant. You’ll need to obtain permits, licenses, and approvals from local authorities. These may include environmental clearances, food safety certifications, and operational licenses. Compliance with local regulations is not just about avoiding penalties; it’s also a critical factor in building trust with your customers and partners. Make sure to engage with local experts who can guide you through the regulatory requirements and help ensure that your plant meets all necessary standards.

7. Packaging and Marketing

The final step in your production process is packaging the refined oil in consumer-friendly containers. But packaging is more than just a protective measure; it’s also a critical component of your branding strategy. Investing in modern packaging lines that can handle various container sizes and formats will help you cater to different market segments. Once your product is ready, a strong brand identity and marketing strategy are essential to penetrating the market and competing with established brands. Understanding local consumer preferences and leveraging digital marketing channels can give you an edge in this competitive market.

Looking Ahead: The Profit Potential in Africa

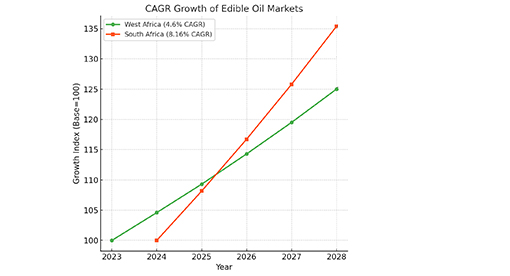

At this point, you might be wondering whether all this effort is worth it. The answer is a resounding yes. The cooking oil business in Africa offers substantial profit margins, with some markets seeing returns of 17% to 38%. The edible oil market in West Africa, for example, is projected to grow at a compound annual growth rate (CAGR) of 4.6% from 2023 to 2028. This growth is driven by rising disposable incomes, changing dietary habits, and the increasing popularity of processed foods.

In countries like South Africa, the edible oil market revenue is expected to reach $239.80 million in 2024, with a projected CAGR of 8.16% between 2024 and 2028. These figures indicate a thriving market with plenty of opportunities for new entrants. Entrepreneurs willing to invest in quality production and effective distribution strategies can find success in this expanding market.

Understanding the Basics: Steps in Edible Oil Refining

For those new to the industry, the edible oil refining process may seem complex. However, it follows a series of well-established steps, each designed to ensure the final product is safe, stable, and of high quality. Here’s a brief overview of the basic steps:

Degumming: Removes phospholipids and other impurities that can affect the oil's quality. This step involves heating the crude oil and treating it with water or an acid to hydrate the gums, which are then separated.

Neutralization: Eliminates free fatty acids that can cause off-flavors and odors. The oil is treated with a caustic soda solution, neutralizing the FFAs and forming soap stock, which is removed.

Bleaching: Removes color pigments and other impurities to improve the oil’s appearance. The oil is mixed with bleaching earth or other adsorbents and then filtered to remove the impurities.

Deodorization: Removes volatile compounds that contribute to undesirable odors and flavors. The oil is subjected to high-temperature steam distillation under vacuum conditions.

Winterization (Optional): Removes waxes and other solids that can cause cloudiness at low temperatures.

Fractionation (Optional): Separates the oil into different components based on melting points, allowing for the production of specialty oils.

Hydrogenation (Optional): Converts unsaturated fats into saturated fats to improve stability and shelf life.

These steps ensure that the final product meets the stringent quality standards required for edible oils.

Conclusion

Setting up an edible oil refining plant in Africa is a venture that requires careful planning, substantial investment, and a deep understanding of both the local market and the refining process. However, the potential rewards are significant. With the right approach, your plant can become a key player in the African market, contributing to the continent's growing demand for high-quality edible oils.

At Myande Group Co., Ltd., we’ve had the privilege of supporting clients in more than 80 countries as they navigate the complexities of setting up successful edible oil refining plants. Our experience has taught us that success in this industry is not just about technology and machinery; it’s about understanding the market, building strong relationships, and continuously striving for excellence. I hope this article has provided you with valuable insights, and I look forward to being a part of your journey as you explore the opportunities in Africa.