Wheat Starch

Transform Your Wheat Starch Production with Myande’s Advanced Technology

Myande wheat starch processing technology adopts three-phase decanter separation method to produce wheat starch and wheat gluten powder from wheat flour. Decanter separation has the advantages of lower water consumption, better product quality and higher dry-matter yield compared with washing process.

Myande has rich experience in wheat processing technology that effectively improves yield of A-starch, reduces drying amount of B-starch and pentosan, and increases water absorption rate of gluten powder.

We provide turnkey wheat starch plant for you with capacity ranging from 200t/d to 2,000t/d.

Pioneering Solutions in Wheat Starch Deep Processing

Myande’s wheat starch processing technology encompasses a comprehensive suite of equipment designed to maximize yield and efficiency. This includes the recovery of A-starch, B-starch, vital gluten, and pentosan.

A-starch, primarily used for glucose and native starch production, is extracted using highly efficient decanter centrifuges and separators, ensuring maximum purity and minimal resource consumption.

B-starch, often utilized in ethanol production or as animal feed, is concentrated and dewatered with advanced technology that reduces energy usage while improving product quality.

Vital gluten, essential for food applications, is carefully separated and processed to maintain its functional properties, meeting the strictest quality standards for human consumption.

Pentosan, a valuable by-product, is efficiently separated and can be further processed for use in animal feed or other industrial applications.

Myande’s wheat starch deep processing equipment is designed with your specific needs in mind. Our solutions integrate advanced features such as three-phase decanter centrifuges, customizable to handle varying raw material qualities with precision. Leveraging innovative technologies like our energy-efficient MVR evaporators and high-performance separators, we help you achieve optimal separation of starch, gluten, and other valuable components with minimal resource consumption. Our systems are developed in close collaboration with industry experts, ensuring they meet the highest standards of performance and reliability. Partner with Myande to benefit from technology that is not only robust but also adaptable to the ever-evolving demands of the global starch industry.

Flour Conveying and Storage

Myande provides bucket elevators, drag conveyors, screw conveyors and other conveying equipment and customize different sizes silos to meet the needs of customers. According to the space and process requirement of customers, the silos and various conveying equipment can be reasonably arranged.

Main equipment: Screw Conveyor, Drag Conveyor

Gluten Separation

Flour is mixed with water at a certain proportion and sent to a three-phase decanter for separation after homogenization. Through centrifuge separation A-starch/fiber, protein /B-starch, and pentosan are obtained. Three-phase decanter has high separation efficiency. It requires less water consumption and ensures stable product quality.

Gluten Washing, Dehydration and Drying

B-starch is separated from gluten by screening. Gluten is sent to screw press for dehydration after multiple-stage washing. After dehydration, gluten is conveyed to drying system. The water absorption rate, fineness and moisture of product gluten are up to or higher than the international advanced level, and the power consumption and steam consumption have obvious advantages in the industry.

Main equipment: Screw Press

Starch Refining and Drying

A/B starch is screened to remove fiber, and then washed and refined, and sent to flash dryer for drying. Multistage filtration is adopted in the air filtration system to ensure that the products meet the requirements of food grade. High speed and low speed air drying systems can meet the needs of different customers.

Main equipment: Flash Dryer

They trust and choose Myande

More than 1,200 complete plants have been supplied under Myande’s name in over 80 countries since 2003.

Behind every successful project is a great team. Our team is comprised of skilled individuals that share one common goal – Help our clients succeed.

What can we do for you?

We focus on supplying one-stop engineering service covering general layout plan, process design, R&D, equipment manufacturing, automatic control system, data integration, installation, supervision, commissioning, training and etc.

Our custom solutions come from a deep understanding of your needs, and we have the capability to complete each project from the design of the initial concept to manufacturing, installation, commissioning and delivery.

Solution Tailored to Your Needs

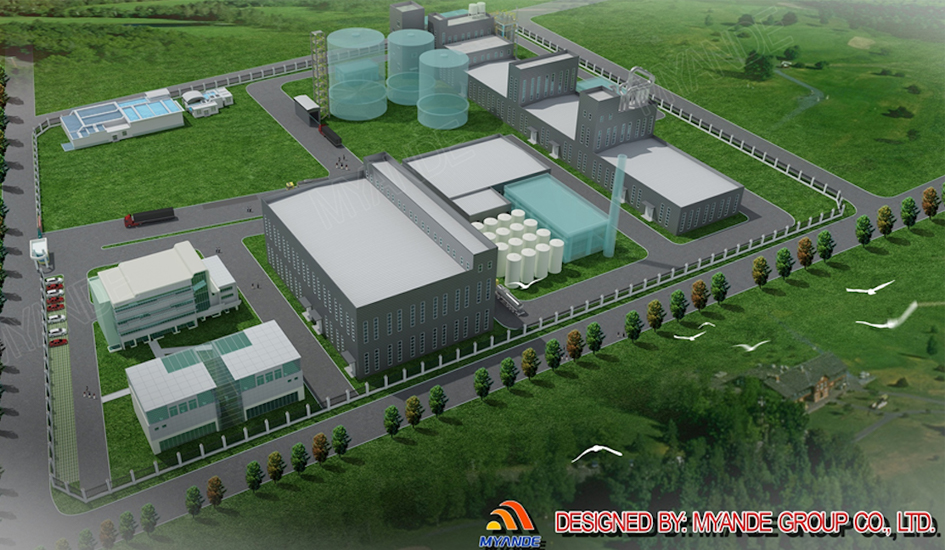

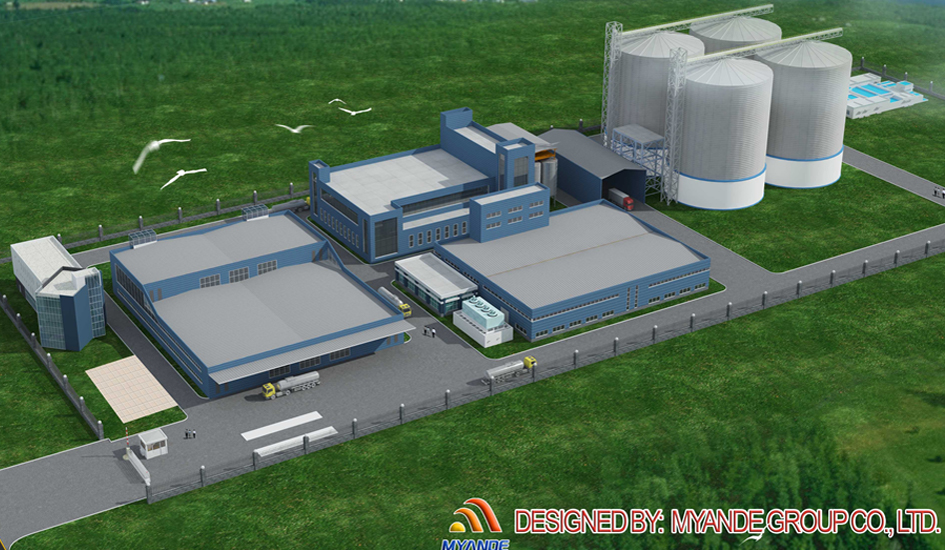

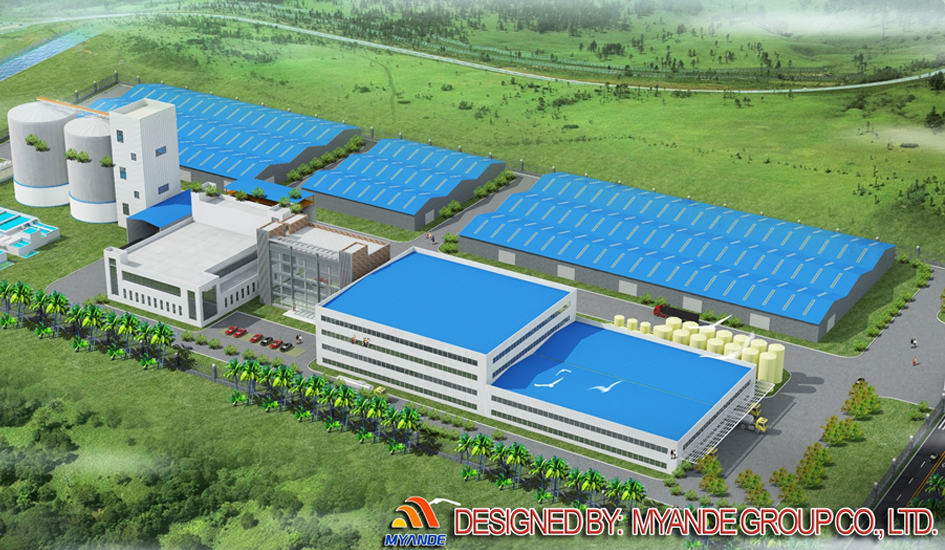

General Layout Plan

With a land prepared, the next thing you should consider is planning the general layout, which is a crucial foundation of a sustainable and cost-effective manufacturing.

Turn to us for help and we will present you the design for your plant by considering water, steam, electricity supply and etc.

Process Design

Combining our engineering expertise, industry know-how and practical skills with your knowledge, we provide the optimized and customized process design for your plant.

3D Plant Design

On the basis of plant layout design, combined with real situation, we can design a three-dimensional model of the entire plant. All the equipment, piping and instruments, any detail can be shown in the model, not only allowing you to have an intuitive understanding of the plant, but also providing overall information support for plant construction, equipment installation and future expansion.

Automatic Control System

We offer economical and most effective process automation solutions for the entire production line. Our RES automatic control system is developed based on PLC/DCS system.

Data Integration

From the perspective of the overall operation of the factory, Myande intelligent data integration management system collects basic data from raw grain procurement, warehousing, processing, inventory, sales and logistics, relying on the interconnection network system of each workshop. It provides real-time, accurate and traceable data reports for the current storage, processing and shipping.

Equipment Manufacturing

We owns in-house manufacture base of more than 130,000㎡ integrating R&D, production, project management which represents advanced engineering capability in the industry.

Installation and Commissioning

After finishing the installation of all machines, we offer on-site commissioning service to ensure compatible functioning.

Every move of the machine needs strong technical support from our experienced engineers. The only principle is that you can start manufacturing right after the commissioning.

Training and After-sales Service

Myande 360° Service Portfolio covers all your needs throughout the life cycle of your project. By minimizing your total cost of ownership, we help you stay ahead of the competition.

About Myande

Myande Group is a globally leading supplier of complete plants, equipment, and services for Oils & Fats, Starch & Derivatives, Fermentation, Evaporation & Crystallization, Material Storage and Handling and Smart Factory industries.

Myande Group currently has 1,300+ employees including 600 technical staff and 700 manufacturing workers. More than 1,200 complete plants have been supplied under Myande’s name in over 80 countries since 2003.

World-leading manufacturing base

In-house manufacture base of more than 130,000㎡ that integrates R&D, production, and project management, representing world-class engineering capability in the industry.

No Compromise on Quality

We are highly committed to Quality Assurance.

Our facilities and processes adhere to the highest local and international industry standards and certifications and are audited regularly for compliance.

With a global quality management system, we ensure that our customers all over the world receive high-quality, reliable products and solutions. We are well aware that our equipment have to function safely and efficiently for decades.

To effectively carry on the spirit of artisanship, improve the overall quality of front-line employees, we hold the “Workmanship Skills Competition" every year.

Certificates & Patents

At Myande, innovation is the result of the total process of developing an idea into a product or a new way of working which adds value to the business.

Over 500 registered patents and utility models demonstrate the company's innovation potential.

Our Global Presence

We focus on supplying one-stop engineering service covering general layout plan, process design, R&D, equipment manufacturing, automatic control system, data integration, installation, supervision, commissioning, training and etc.

Our custom solutions come from a deep understanding of your needs, and we have the capability to complete each project from the design of the initial concept to manufacturing, installation, commissioning and delivery.

You might also be interested in

Related Products

Lifecycle Service

Technical expertise and innovative products form the basis of your success. But we offer you even more: our extensive range of services gives you optimum support for your requirements and objectives in the long term.

Myande News & Insights

2,000TPD Rapeseed Crushing Plant Launched

Recently, a 2,000 t/d rapeseed crushing plant built by Myande Group for Daodaoquan Grain and Oil Co., Ltd. started operation successfully and started to yield qualified rapeseed oil and meal. Daodaoquan Grain and Oil Co., Ltd. is a comprehensive oil processing enterprise integrating production, scientific research, trade, warehousing and logistics of edible vegetable oil and its related by-products. This new rapeseed crushing plant incorporates a wide range of Myande core equipment possessing independent intellectual property rights, including the E-type extractor, hydraulic flaker, DTDC, conditioner, and other key equipment. To achieve flexible material incoming and discharging, Myande CCJL series sweep auger and CQJL series reclaimer are used. In addition, advanced energy-saving technology, negative pressure draining technology and intelligent safety technology are used to ensure the stable operation of the entire production line and excellent product index. With the concept of "creating the best performance for our customers", Myande cooperates with DaoDaoQuan to build a modern, energy-efficient, and environmentally friendly factory.

600,000 T/A Wheat Starch Deep Processing Project Successfully Launched

Recently, the 1st phase of Henan Hanyong's 600,000 tons (annual output) wheat starch deep processing project, designed by and installed under the guidance of Myande, has been smoothly commissioned, and contract for the 2nd phase was signed with Myande, marking the further extension of the domestic wheat deep processing industry chain. Henan Hanyong Biotechnology Co., Ltd. is one of the leading enterprises in agricultural industrialization of Henan province. It mainly produces edible alcohol with strong competitiveness and a high reputation in the market. Starch deep processing is one of Myande’s important business segments. After years of technology and experience accumulation in the field of starch deep processing, Myande has formed a complete set of production design system with a high degree of automation, stable operation and high product quality. In recent years, Myande has successfully established long-term strategic cooperative relations with multiple famous domestic and international enterprises. Combining with Hanyong's own industrial advantages, after in-depth research, efficient communication and repeated demonstrations, Myande has designed a set of production plan (as shown in the following figure) specially for the customer, and it can not only produce gluten and wheat starch, but also make better use of the mixed nutrient solution of process water and pentosan to produce alcohol, which will bring considerable economic benefits. The 1st phase project is a 500tpd wheat flour processing project, including a 3tpd gluten drying system and a 12tpd starch drying system. From beginning to end, the whole project lasted for 10 months. During the whole implementation process, from the plant layout planning, process design, intelligent automation design in the early stage, project service in the mid-term, to the installation, commissioning and training in the post stage, Myande’s rigorous, attentive and efficient one-stop service has won the unanimous praise of Hanyong. Through the joint efforts of Myande and Hanyong employees, a brand-new starch deep processing production line was successfully commissioned and started running smoothly, and all indicators were superior to the technical level of the same industry. In view of the pleasant cooperation in the 1st phase, Hanyong decided to cooperate with Myande again to expand its wheat starch deep processing output, and signed the 2nd phase project with Myande resolutely, namely 5t/d gluten drying system and 20t/h starch drying system. After which, Hanyong will become a high-quality gluten high-value conversion base with "the largest scale, the best environment protection and the highest level of research and development" in the industry in Asia.

Future Trends in the Global Starch Deep Processing Industry

Currently, the competition landscape of the global starch deep processing industry is quite complex, with major markets concentrated in North America, Europe, and Asia. According to market research data, the largest companies in the global starch deep processing market include ADM, Ingredion, Tate & Lyle, Roquette, etc. The main areas of starch deep processing include: 1. Food processing: processing starch raw materials into various food products and additives, such as biscuits, candy, noodles, fructose, glucose, etc. 2. Industrial uses: processing starch raw materials into various industrial products, such as paper, glue, textiles, biomass fuels, etc. 3. Pharmaceuticals and cosmetics: processing starch raw materials into medicines, health products, and cosmetics, etc. According to market research, the global starch deep processing market had a capacity of approximately 31 million tons in 2021, and is expected to grow at a compound annual growth rate of 3-4% in the coming years. This growth is mainly driven by increasing consumer demand for health and nutrition, as well as the expansion of application areas for starch deep processing products. Additionally, the continuous introduction of new technologies and equipment by starch deep processing enterprises to improve production efficiency and product quality is also a significant factor contributing to market growth. Moreover, the starch deep processing market in Asia has a relatively large size, with China, India, Indonesia, and Thailand having the largest market sizes. The future trends of the global starch deep processing industry include: 1. Diversified products: Starch deep processing enterprises will introduce more different types of products, such as sugar substitutes, beverage concentrates, etc., to meet market demand as consumer preferences evolve. 2. Enhanced functionality: Starch deep processing products will no longer be limited to traditional thickening and stabilization functions, but will focus more on health, nutrition, and other aspects, such as adding prebiotics, probiotics, etc. 3. Automated production: With the continuous improvement of automation technology, starch deep processing enterprises will pay more attention to the automation level of the production line to improve production efficiency and quality. 4. Environmental protection and energy conservation: Starch deep processing enterprises will adopt more environmentally friendly production technologies and equipment, such as recycled water utilization, waste gas treatment, etc., to reduce the environmental impact of the production process. In terms of processing equipment and technology, the future trends include: 1. Intelligent manufacturing: Processing equipment will increasingly adopt digital, intelligent technologies to achieve intelligent, automated control, and data management of the production line. 2. Multi-functionality: Processing equipment will be able to process multiple types of products, such as producing various starches, sugar substitutes, etc., to improve production efficiency and flexibility. 3. Energy conservation and environmental protection: Processing equipment will use more energy-efficient and environmentally friendly designs and materials, such as using renewable energy sources and reducing wastewater and waste gas emissions, to reduce energy consumption and environmental pollution during the production process. 4. Precision processing: Processing equipment will pay more attention to the precision and controllability of the processing process, such as more accurate measurement and mixing technologies, to improve product quality and consistency. To enter the starch deep processing industry, the following preparations are needed: 1. Industry research: Understand the development trends, market size, competition patterns, and relevant policies and regulations of the starch deep processing industry, in order to make wise decisions for entrepreneurship. 2. Technology research and development: Starch deep processing is a technology-intensive industry that requires certain technological research and development capabilities to master the relevant processing technologies and production processes. 3. Capital preparation: Entering the starch deep processing industry requires a significant amount of investment, including production equipment, raw material procurement, human resources, and more. It is necessary to evaluate funding requirements and prepare a budget. 4. Talent recruitment: The starch deep processing industry requires professionals with relevant knowledge and skills, such as food science, chemical engineering, etc. In addition, talent in production management, sales and marketing, finance, and other fields is needed. 5. Marketing: The starch deep processing industry is highly competitive and requires effective marketing strategies, including product positioning, brand building, channel development, market promotion, and more. 6. Compliance management: The starch deep processing industry needs to comply with relevant laws and regulations, such as the Food Safety Law and the Environmental Protection Law. It is necessary to develop compliance management systems and strictly enforce them. In summary, entering the starch deep processing industry requires comprehensive consideration of factors such as technology, capital, talent, and market, and the development of corresponding plans and strategies.

Contact Us

Contact us to see how we can help you grow your business.

Find the solution to an optimized future.